In heavy industries, from power generation and chemical processing to refineries, steam is the diligent workhorse. It drives turbines, heats process fluids, and provides motive force. But the very thing that makes steam valuable, its high temperature, is also its greatest challenge to piping integrity. When a steam line heats up from ambient to 1000 °F, effectively becoming superheated steam, the pipe can expand dramatically, creating immense axial forces that threaten to damage anchors, strain pumps, and cause catastrophic failure.

This is where the single expansion joint earns its title as the steam system MVP.

The Problem: Unrestrained Thermal Growth

Steam distribution systems often feature long, straight runs of pipe. The thermal expansion along these lengths is significant and is calculated as pure axial movement: the pipe simply gets longer.

If this movement is not absorbed, it results in:

- Massive Anchor Loads: Fixed points must withstand thousands of pounds of compressive force, leading to oversized, expensive support structures.

- Equipment Damage: Pumps, valves, and heat exchangers connected to the pipe are subjected to stress, causing premature failure, misalignment, and increased maintenance.

- Pipe Buckling: If the line is improperly guided or supported, the immense force can cause the pipe to bend or buckle.

The Solution: The Efficiency of the Single Expansion Joint

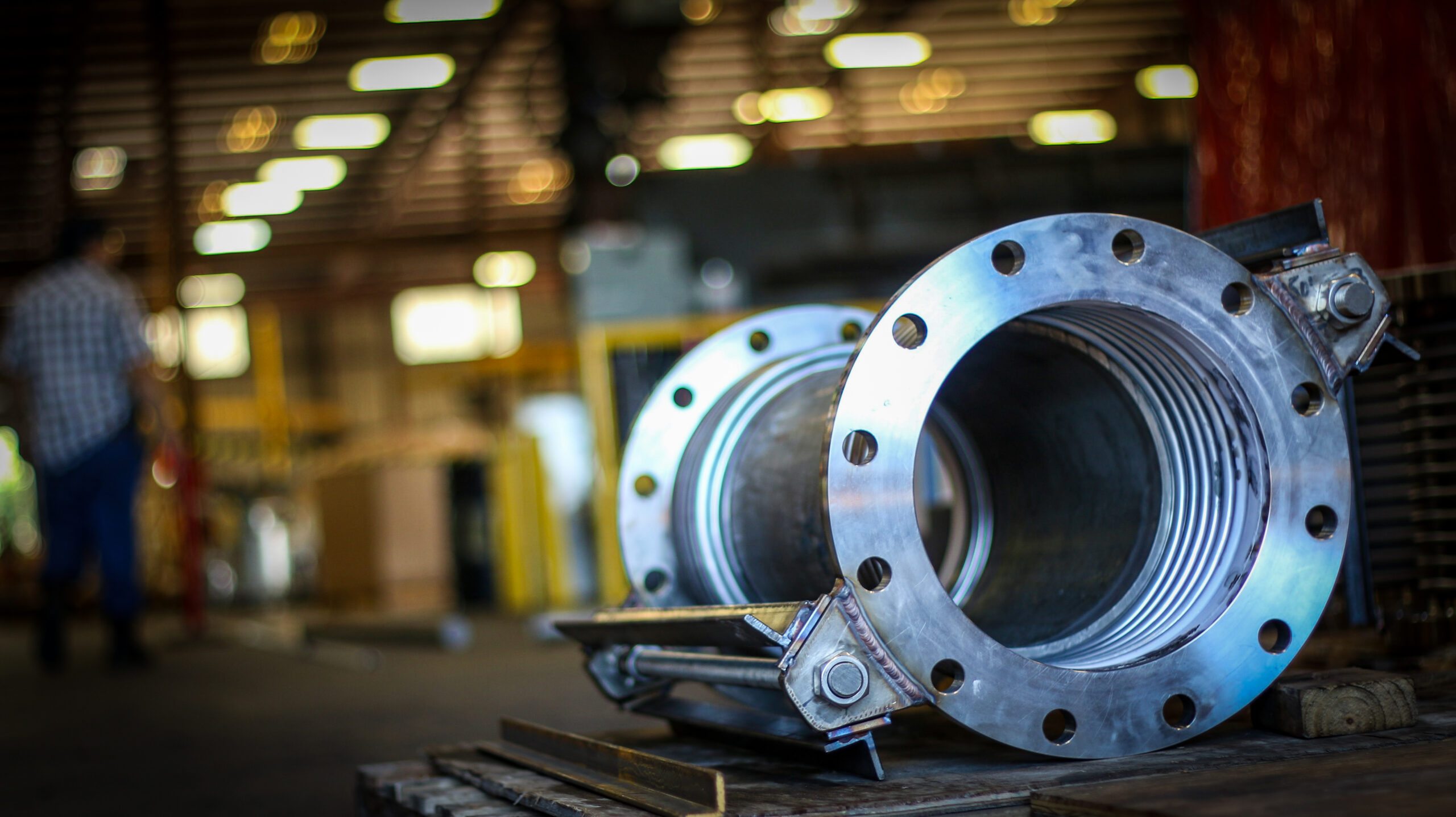

The single expansion joint, consisting of one bellows element and end fittings, is the most direct, cost-effective, and efficient component for handling this specific challenge: pure axial movement.

Here’s why single expansion joints are the go-to component for critical high-temperature steam distribution:

- Direct Absorption of Axial Movement: They are explicitly designed to compress or extend along the pipe’s centerline, flawlessly absorbing thermal growth without transmitting damaging stresses to connected equipment or supports.

- Compact Footprint: Unlike large, bulky pipe loops that require significant space to bend and accommodate movement, single joints fit neatly within the existing pipe run, minimizing structural engineering costs and conserving valuable plant space.

- High-Pressure, High-Temperature Capability: Constructed from robust materials such as Inconel-625 or specialized stainless steel alloys, single joints can be engineered to withstand the extreme pressures and superheated temperatures typical of modern steam systems.

- Cost-Effectiveness: When the required movement is strictly axial, the single-joint solution is the most economical, requiring less material and a simpler design than universal or pressure-balanced alternatives.

US Bellows: Engineered Reliability for High-Cycle Steam

At US Bellows, we provide engineered certainty for your most critical utility systems. We understand that a failure in a refinery’s catalytic cracking steam line or a power plant’s main steam header is not an option.

For your high-temperature, high-pressure steam systems, US Bellows delivers single expansion joints engineered for maximum cycle life, superior materials compatibility (even in corrosive service), and rapid deployment, safeguarding your critical infrastructure against thermal fatigue and minimizing the risk of expensive, unscheduled downtime.

We custom-fabricate every expansion joint with precision bellows technology to match the exact temperature, pressure, and movement requirements of your application and deliver the best performance in the toughest environments.

Don’t Let Thermal Stress Compromise Your Steam System

Whether you’re dealing with live steam, auxiliary steam, or boiler feed lines, securing your piping against the forces of thermal expansion is essential for continuous operation and safety. Rely on the engineered performance of our single expansion joint.

Contact US Bellows today for a consultation on how our single expansion joints can address your high-temperature piping needs.