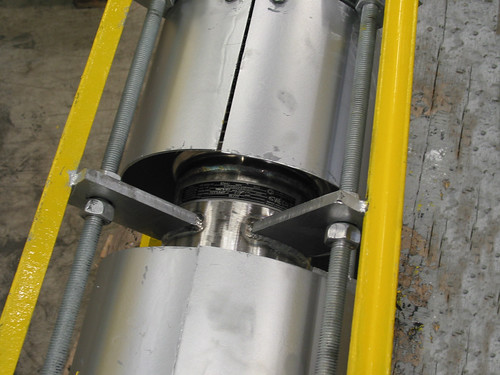

U.S. Bellows, Inc. recently fabricated 60 dia. refractory lined universal expansion joints for a carbon monoxide ducting system at a chemical refinery. The expansion joints are lined with a 3/4″ thick abrasion resistant refractory lining with hexagonal mesh reinforced anchor. A240 TP 304 material was used to fabricate the bellows and flanges and A240 TP 310 material was used for the spool. Designed for 2 PSIG, the joints were air tested at 5 PSIG to ensure quality performance. A dye-penetrant test was also implemented on the bellows’ long seam and attachment welds. These expansion joints were fabricated and designed per B31.3 and EJMA standards.

Read More