Industrial Expansion Joints Explained: Fabric, Rubber, and Essential Accessories

Industrial ductwork in power generation and chemical processing faces three main challenges: thermal expansion, vibration, and misalignment.

The solution to preventing leaks and structural damage is the use of engineered fabric and rubber expansion joints. Think of expansion joints as the shock absorbers of your industrial piping; without them, every bump in temperature or pressure rattles the entire frame until something breaks.

This guide explores the differences between fabric and rubber expansion joints, as well as the essential accessories required to build a resilient system.

Fabric vs. Rubber Expansion Joints: Which Is Right for You?

Selecting the correct expansion joint depends heavily on the specific environmental factors of your operation, such as temperature, pressure, and the presence of corrosive elements.

When to Choose Fabric Expansion Joints

Fabric expansion joints are engineered for flexibility and high-heat environments. They are the best choice for:

- High-Temperature Applications: They excel in environments like flue gas ducts, and fabric joints can be insulated for extreme temperatures

- Low-Pressure Systems: Best suited for applications where pressure is not the primary stressor. In general, fabrics are limited to +/- 100” of water column.

- Complex Movements: These joints can handle significant multi-plane movements, including axial, lateral, and angular shifts, all in a relatively short span of length in the ductwork

- Minimize Reactive Forces: Fabric joints are lightweight, exerting minimal reactive forces on equipment and making them ideal for large-diameter ductwork and exhaust applications.

- Maintenance: Because it is lightweight, fabric joints can be easily maintained and replaced. One can only replace the fabric, not the entire frame of the expansion joint.

- Corrosive Environments: Fabric joints offer high resistance to corrosive gases and harsh chemicals, especially PTFE Fabrics

Considerations

- Leak-tight Applications: While many fabrics can be leak-tight, you will see leakage at fabric attachments to your ductwork, whether via clamps, retaining bars, or bolts.

When to Choose Rubber Expansion Joints

Rubber expansion joints are the industry standard for liquid handling and vibration control. They are ideal for:

Rubber expansion joints are the industry standard for liquid handling and vibration control. They are ideal for:

- Vibration-Heavy Systems: Excellent at vibration dampening and noise reduction.

- Liquid Systems: specifically designed for pumping systems, chillers, and water/wastewater treatment plants.

- Moderate Corrosion Resistance: Rubber offers good sealing and water resistance. Specific rubber compounds are key for common chemicals, weathering, and UV.

- Longevity: In the right environment, rubber joints are long-lasting and maintenance-free.

Considerations

- Extreme temperatures (High Temps or Cryogenic): Rubber joints are not meant to handle high temperatures. In these situations, consider metal or fabric. By the same token, at cryogenic temperatures, rubber is brittle and not recommended.

- High Pressure: Rubber joints can withstand up to 300 psi, depending on the diameter; for larger diameters, the pressure rating decreases. Metal joints need to be considered for high pressures.

Common Questions: Essential Expansion Joint Accessories

An expansion joint is only as effective as the system it is part of. To get the best performance and safety, engineers should integrate specific accessories to protect the infrastructure from heat, erosion, and stress.

What is the function of flow liners?

Flow liners are critical components that increase gas flow efficiency in ductwork. They serve a dual purpose by protecting the expansion joint itself from abrasive media flowing through the system.

Why are Insulation pillows necessary?

Insulation pillows provide thermal protection for the joint. They are essential for maintaining system temperatures while protecting the expansion joint from heat damage.

How do flanges and backing bars improve safety?

Flanges and backing bars are mechanical components that ensure a secure, leak-proof connection to the ductwork. They improve safety and longevity by distributing the load evenly across the connection point.

Building a Resilient System with US Bellows

Pipe stress should not jeopardize your operations. By selecting the right combination of fabric or rubber expansion joints and integrating essential accessories like flow liners, you can build a more resilient ductwork system.

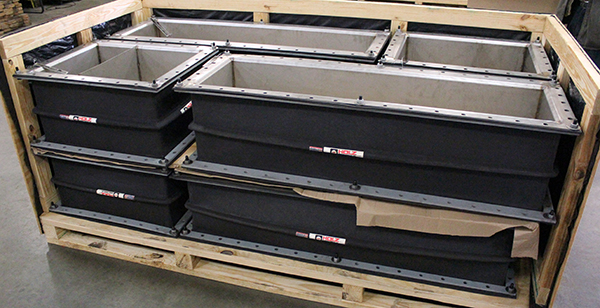

US Bellows engineers resilience into your operations. We provide the precise combination of fabric or rubber expansion joints and essential accessories to absorb stress, eliminate leaks, and ensure your ductwork performs efficiently for years to come.

Stop Unscheduled Downtime

Are you unsure if your current ductwork can handle the stress of thermal expansion or vibration? Book a meeting with a US Bellows engineer to conduct a system assessment and determine the right expansion joint for your piping operation.