The success of any high-temperature industrial process, from petrochemical refining to power generation, hinges on the integrity of its refractory lining. However, the aggressive thermal cycles these systems endure can subject the lining and its containment vessels to mechanical stress. This is where the workhorse of high-temperature engineering steps in: the expansion joint.

The Critical Interface: Expansion Joints and Refractory

Refractory materials, typically ceramic or concrete, are designed to insulate and protect steel components from extreme heat. Yet, they possess a relatively low tensile strength and are highly susceptible to cracking and spalling when subjected to differential thermal movement.

Refractory materials, typically ceramic or concrete, are designed to insulate and protect steel components from extreme heat. Yet, they possess a relatively low tensile strength and are highly susceptible to cracking and spalling when subjected to differential thermal movement.

An expansion joint, integrated into the ductwork or piping system, absorbs the axial, lateral, and angular movement caused by thermal expansion and contraction of the surrounding steel structure. By managing this movement, the expansion joint prevents stresses from being transferred directly into the brittle refractory material, thereby maintaining the system’s structural integrity and keeping the piping’s internal insulation intact.

Key Considerations in Refractory Selection

Choosing the right refractory is only half the battle; ensuring the expansion joint is compatible with the refractory and the operating environment is paramount. Here are the factors an engineer must consider:

- Maximum Operating Temperature: This dictates the material for both the refractory and the metallic or fabric expansion joint elements. The insulation thickness will also determine the temperature of the piping and the bellows.

- Refractory thickness Trade-off: A thicker refractory lowers piping temperature, allowing the use of cheaper steels such as Carbon steel; however, the piping will be heavier, requiring larger loads and supports. A thinner refractory will yield a higher shell temperature, and the use of stainless steel or alloys for the piping will lower the pipeline’s weight.

- Chemical Environment: The presence of corrosive gases (such as SOx or NOx) or particulate matter can lead to premature degradation, requiring specialized alloys or fabric coatings, as well as abrasion-resistant refractories

- Thermal Expansion Coefficient: Understanding the difference in expansion rates between the steel duct, the refractory material, and the expansion joint’s liner and bellows is crucial for designing the correct gap and insulation scheme.

- Vibration and Fatigue: Systems with high flow rates or cycling operations require bellows designed to withstand the resulting fatigue stress. Vibration may be an issue for refractory, potentially leading to cracking if not accounted for during design.

Protecting the Heat: Integrating Expansion Joints

Mastering Movement: How Expansion Joint Design Preserves Refractory Integrity

The biggest threat to a refractory-lined pipe is the uncontrolled force generated by the thermal expansion of the surrounding steel ductwork. A properly selected and installed expansion joint acts as a pressure-relief valve for mechanical stress, thereby directly extending the service life of the refractory and the piping system.

The Essential Role of Liners and Internal Insulation

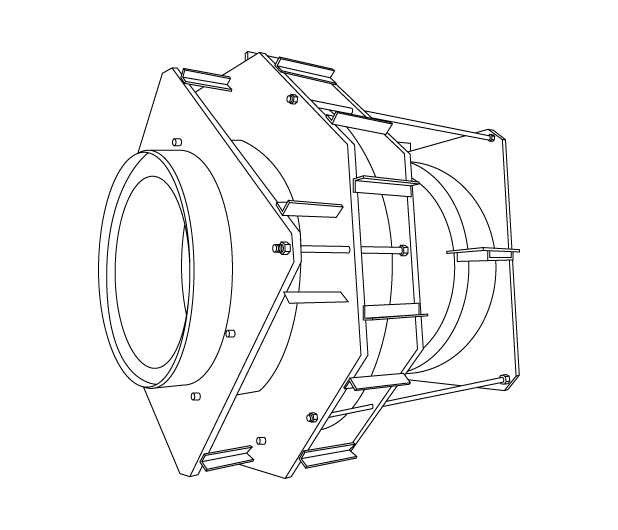

The protection of the expansion joint itself is critical. High-temperature metal bellows are often protected internally by a flow liner and refractory insulation.

The flow liner serves a dual purpose: it smooths the flow of media past the bellows, reducing turbulence and vibration-induced fatigue, and it acts as a mechanical barrier to the internal insulation. This internal insulation, often ceramic fiber or a castable refractory material, shields the bellows material from the highest process temperatures. The liner must be designed to allow the bellows to move freely without compromising the insulation’s integrity during the line’s thermal cycling.

This reduction in thermal gradient is critical, as it allows the use of lower-temperature-rated bellows alloys, which are better suited for cyclic operation due to improved cycle life, without the creep phenomenon becoming an issue under constant stress on the bellows. Without this integrated protection, the bellows would be subjected to higher temperatures and operate in the bellows material’s creep range, leading to premature failure.

US Bellows: Your Partner in Customization

At US Bellows, we specialize in custom, refractory-lined, high-temperature expansion joints that are pre-engineered to match the thermal expansion coefficients and chemical composition of your specific refractory system. Our custom solutions minimize stress transfer, virtually eliminate refractory spalling, and drastically reduce the costly downtime associated with high-temperature system failure, providing you with predictable, sustained operational success.

Stop settling for generic solutions that fail under the heat. Contact a US Bellows high-temperature specialist today to design a refractory-matched expansion joint solution that guarantees the maximum service life for your critical assets.