The Foundation: Understanding the Role of Bellows Design Standards

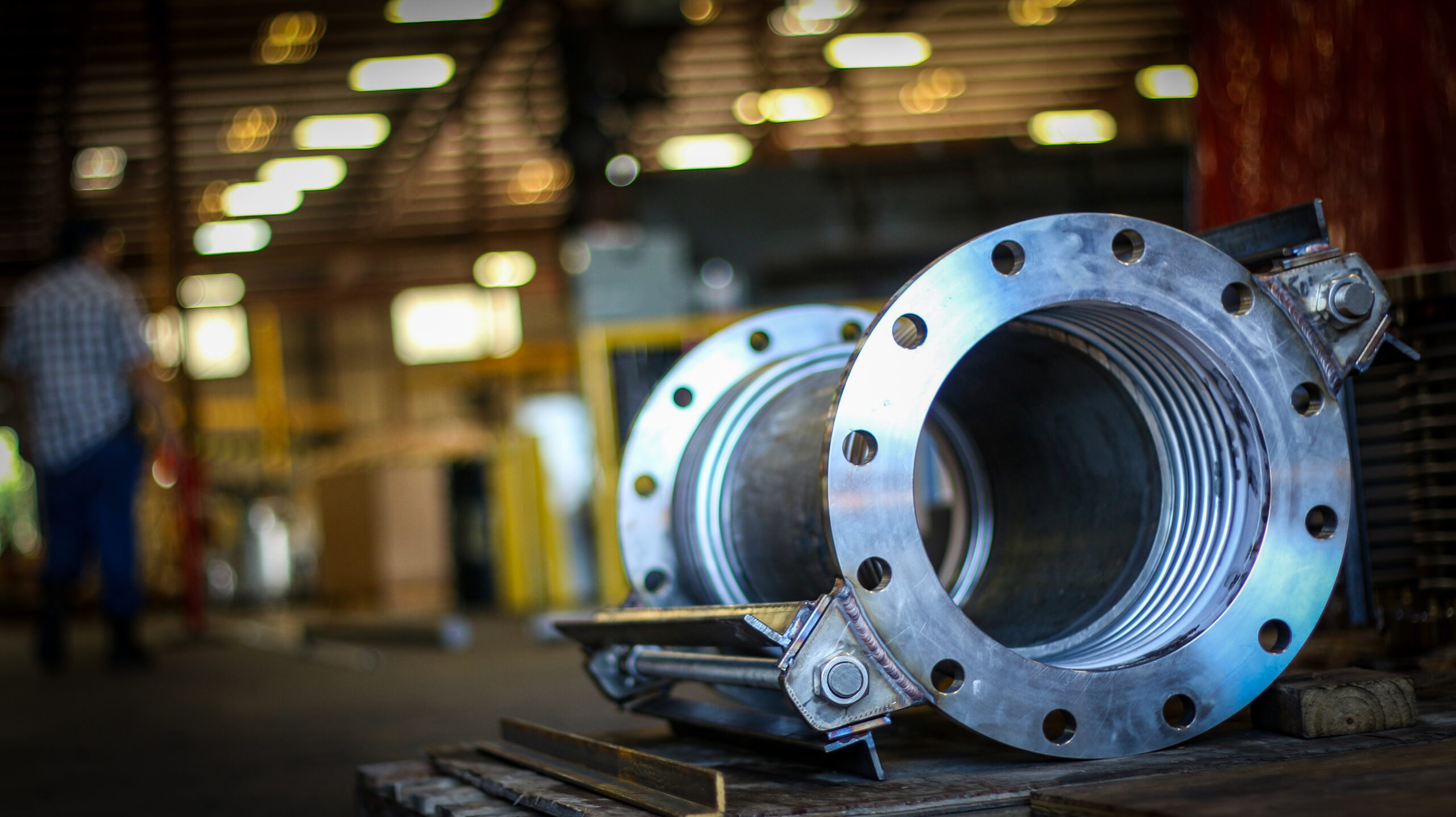

Expansion joints are the critical, yet often most stressed, components in any piping system, designed to absorb thermal movement, vibration, and pressure changes. Ensuring their reliable performance requires strict adherence to codified design principles. In the industrial world, two organizations primarily govern the design and application of metallic bellows expansion joints: the Expansion Joint Manufacturers Association (EJMA) and the American Society of Mechanical Engineers (ASME).

While both organizations strive for safety and reliability, they approach design, particularly fatigue-life calculations, with distinct philosophies. EJMA provides the fundamental industry-specific guide, establishing the nomenclature, formulas, and best practices verified by manufacturers’ testing. ASME, on the other hand, is the overarching pressure equipment code that governs piping systems (e.g., ASME B31.3) and pressure vessels (ASME Section VIII).

EJMA vs. ASME: The Critical Difference in Cycle Life and Safety

The most significant and often confusing difference between EJMA and ASME design calculations lies in their respective fatigue curves used to predict the service life (or cycle life) of the bellows element.

| Feature | EJMA Standards (The Practical Guide) | ASME Code (e.g., B31.3 Appendix X) |

| Design Philosophy | Focuses on practical cycle prediction based on extensive manufacturer testing. | Focuses on conservative safety margins required by pressure vessel and piping codes. |

| Fatigue Curve | It is a “best fit” curve representing the expected average cycle life. | A more conservative curve that results in an expansion joint design in line with ASME piping codes. |

| Safety Factor | No inherent safety factor is included in the cycle-life calculation itself, so designers are expected to add their own margin. | Design margins and safety factors are inherently included in the curve, resulting in a much lower calculated cycle life for the same bellows. |

| Calculated Cycle Life | Significantly higher. Provides the most practical estimate of bellows’ lifespan. | Significantly lower. Provides a guaranteed minimum life based on stringent code requirements. |

In short, a bellows designed to EJMA standards may have an estimated cycle life of 7,000 cycles. In comparison, the same bellows, calculated using the latest ASME B31.3 Appendix X cycle-life calculation, might yield only 1,150 cycles. This difference is not a flaw in either standard, but a reflection of the margin of safety built into the ASME code to guarantee system integrity.

Compliance and Integration: Where the Standards Align

Despite differences in cycle-life calculation, the two standards are not entirely independent; they often overlap and rely on each other to complete a design. In fact, ASME B31.3 code incorporates the EJMA standard into its design but modifies it to fit within its own framework.

-

- Shared Foundation: Both EJMA and ASME derive their fatigue curves from the same initial set of empirical test data collected from bellows manufacturers.

- Structural Components: EJMA standards require that all external hardware (such as tie rods, hinges, and gimbals) necessary to manage pressure thrust and movement be designed using accepted methods based on elastic theory, which often means meeting the allowable stresses and design principles outlined in ASME B31.3 and BPVC.

- Material Properties: Material allowable stresses, which are foundational to any pressure design, are typically derived from ASME Boiler and Pressure Vessel Code (BPVC) Section II, Part D.

- Buckling/Squirm: Factors of safety for structural instability, such as column squirm (typically 2.25), are explicitly mandated by EJMA equations, aligning with requirements in piping codes such as ASME B31.3.

- Hydrotesting: ASME B31.3: Requires testing the expansion joint at the unit’s design temperature, which may result in a higher test pressure.

A piping system built in the US or in many global markets will require the expansion joint assembly to be designed to the EJMA standard for the bellows element while ensuring the entire joint’s construction, materials, and structural attachments comply with the applicable ASME code (e.g., B31.3, B31.1, or Section VIII).

US Bellows Delivers Bellows Performance and Safety

When navigating the differences between EJMA’s optimized design and ASME’s stringent compliance, you need a partner with genuine expertise.

At US Bellows and our parent company, Piping Technology & Products (PT&P), we engineer solutions that balance performance and compliance.

As a longstanding member of the Expansion Joint Manufacturers Association (EJMA) and a leading ASME-certified fabricator (Section VIII), our teams can interpret and apply the complexities of both code systems. PT&P is the only company globally to combine deep, proprietary pipe stress engineering expertise with in-house manufacturing of expansion joints and pipe supports. This means our experts design your bellows with the practical, proven cycle-life assurance of EJMA, while guaranteeing full compliance with mandatory ASME safety margins. Request a quote today to learn more.