Single expansion joints are the unsung heroes of your piping system, quietly absorbing thousands of cycles of thermal movement. Because they’re designed to flex, they endure fatigue over time. While they are built for durability, they aren’t meant to last forever. Proactive visual inspection is your best tool for preventing catastrophic failures that lead to costly unplanned downtime.

For maintenance and inspection teams, knowing what to look for is crucial. Here are five practical visual signs that a single expansion joint is nearing the end of its service life and needs to be replaced.

1. Bellows Thinning or Cracking (Fatigue Failure)

This is the most direct sign of bellows failure, resulting from the cumulative stress of cycles.

- What to Look For: Examine the bellows convolutions (the curved ridges) for fine, hairline cracks, especially in the crests (tops) or roots (bottoms), as well as the weld seam of the metal folds. In high-cycle or vibration applications, you might see pitting or thinning of the metal surface due to constant stress, bending, and work-hardening. Particularly on stainless steel, look for rusty-brown streaks or spots, which can be an early sign of a pinhole leak.

- Why it Matters: Cracks indicate the material has reached its fatigue limit. Once a crack starts, it will propagate more for each additional cycle under pressure, leading to an immediate, full-system leak or rupture.

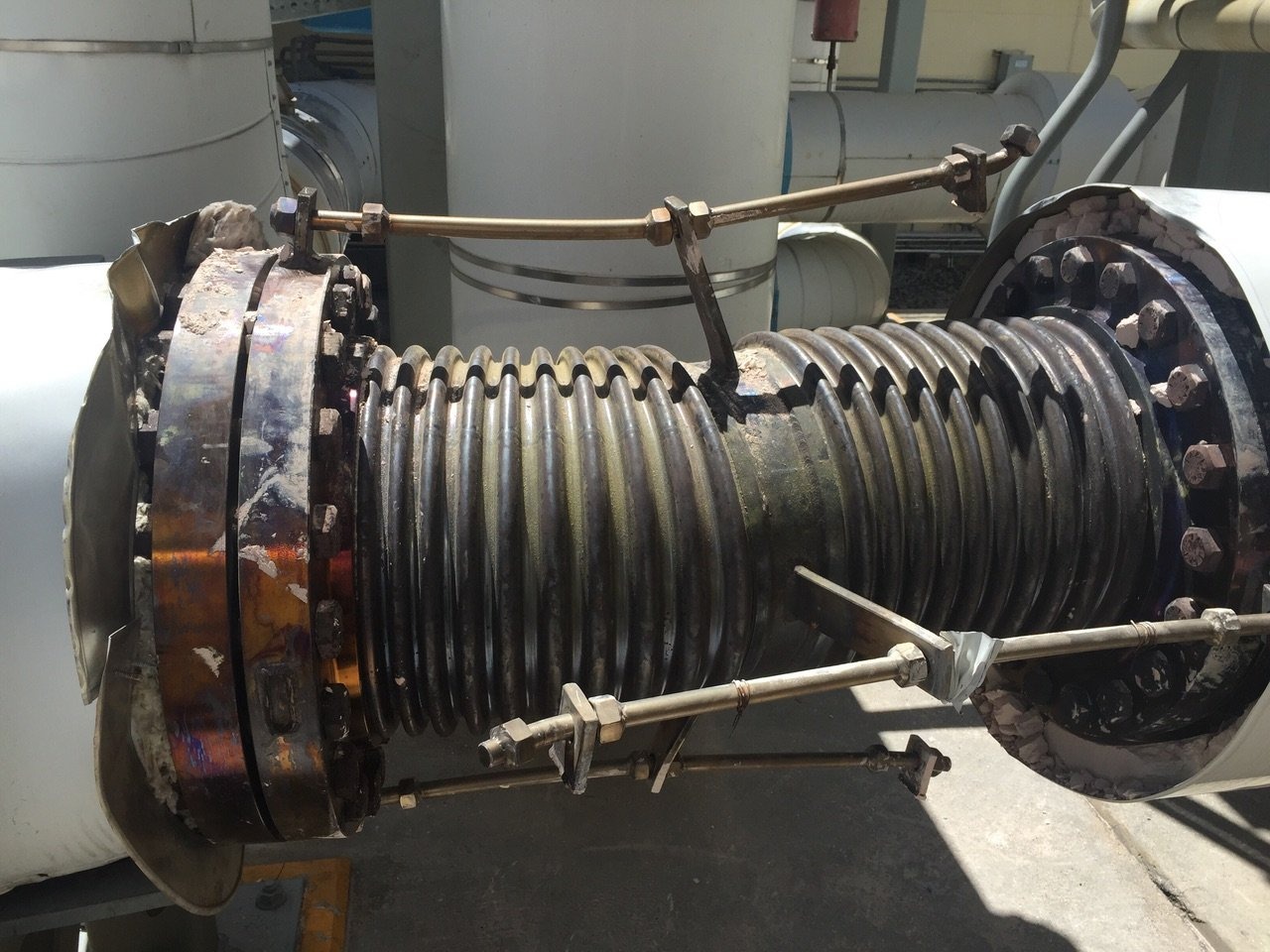

2. Squirm or Localized Bulging of the Bellows

“Squirm” is a term used to describe a lateral instability or buckling of the bellows convolutions under high internal pressure.

- What to Look For: Instead of the convolutions being evenly spaced and uniform, look for one or more convolutions that appear swollen, distorted, or significantly wider than the others. In severe cases, the bellows may be forced out of a straight line, resembling a snake or an “S” curve.

- Why it Matters: This catastrophic deformation occurs when the bellows convolutions can no longer withstand the internal pressure. The bellows’ deformation indicates it can no longer absorb movement correctly, and imminent failure often occurs shortly before a complete rupture.

3. Missing or Damaged Hardware (Tie Rods, Limit Rods, Covers)

While a single expansion joint is primarily designed for axial movement, it may incorporate limit rods or external hardware to provide safety or protection in the event of anchor/equipment failure.

- What to Look For:

- Limit Rods: Check that the rods and the nuts/washers at the ends are intact. If a nut is missing or the nuts are visibly strained against the stop plates, it may indicate the joint is being forced beyond its designed movement capacity and should be inspected.

- Hardware: Check that the lugs and hardware are not bent, and look for cracks in the attachment welds.

- External Covers: If the joint has an external cover (which protects the delicate bellows from external damage, weld splatter, or insulation material), look for dents, missing bolts, or signs that the cover has been broken: this suggests improper installation or external impact.

- Why it Matters: Damaged or missing hardware is often evidence of a pre-existing problem in which the piping system has exceeded the joint’s movement limit, placing immense, unseen stress on the expansion joint.

4. Misalignment & Non-Axial Deflection

Single expansion joints are designed mainly to absorb axial movement (lengthening and shortening along the pipe axis). They cannot handle significant lateral (sideways) or angular (bending) movement.

- What to Look For: Visually inspect the joint’s ends. Does the pipe going into the joint line up perfectly with the pipe coming out? If the bellows appear to be bent, sagged, or leaning at an angle, or if the flanges are not parallel, the joint is misaligned and suffering from dangerous non-axial stress. This often occurs during installation errors or when pipe anchors or guides have been compromised or failed.

- Why it Matters: Forcing a single expansion joint to absorb lateral or angular movement dramatically reduces its fatigue life, sometimes to just a fraction of its intended rating, and makes it highly vulnerable to premature failure.

5. Evidence of Corrosion on the Bellows

Corrosion degrades the bellows material, quickly reducing its ability to handle pressure and movement.

- What to Look For: Look for heavy surface rust (on carbon-steel components) or signs of stress-corrosion, cracking (delicate, mud-crack-like patterns, often near welds on stainless steel). This can be caused by exposure to moisture or chemicals (such as chlorides from cleaning agents or insulation). Internally, check for scale or media buildup, which can restrict movement and cause erosion.

- Why it Matters: Corroded metal is thinner and weaker, compromising the bellows’ structural integrity. A bellows that has lost half its wall thickness due to corrosion will fail at a fraction of its original design pressure, regardless of its cycle life.

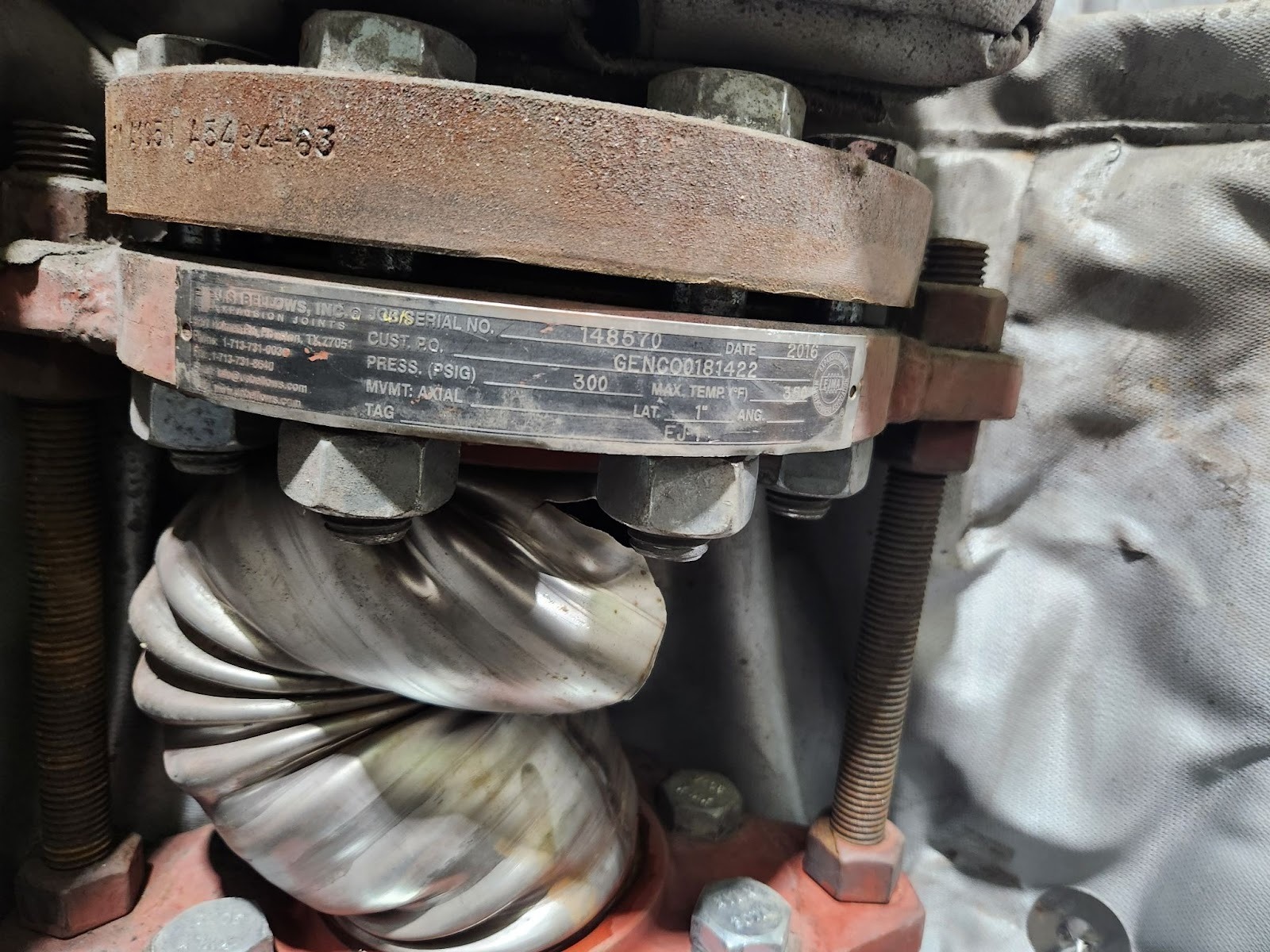

Your Next Step: Call the Experts at US Bellows

Catching these signs early allows for a scheduled, controlled replacement rather than an emergency shutdown. If your inspection reveals any of the five warning signs above, it’s time to consult with an expert.

US Bellows provides rapid assessment, custom design, and quick manufacturing of single expansion joints to replace worn or failed components. Don’t wait for a rupture: partner with us to keep your systems operating safely and efficiently.

Contact US Bellows today for a professional assessment and replacement quote.