Why Choose US Bellows for your ASME Code Expansion Joints?

Our expansion joints are designed and manufactured to meet the rigorous standards of ASME Section VIII, Division 1 & Div.2. This guarantees superior quality, structural integrity, and performance under the most demanding operating conditions.

Every expansion joint undergoes rigorous testing, including hydrostatic and non-destructive evaluations, ensuring compliance with ASME code standards. ASME Third-party inspections further validate our commitment to quality and reliability.

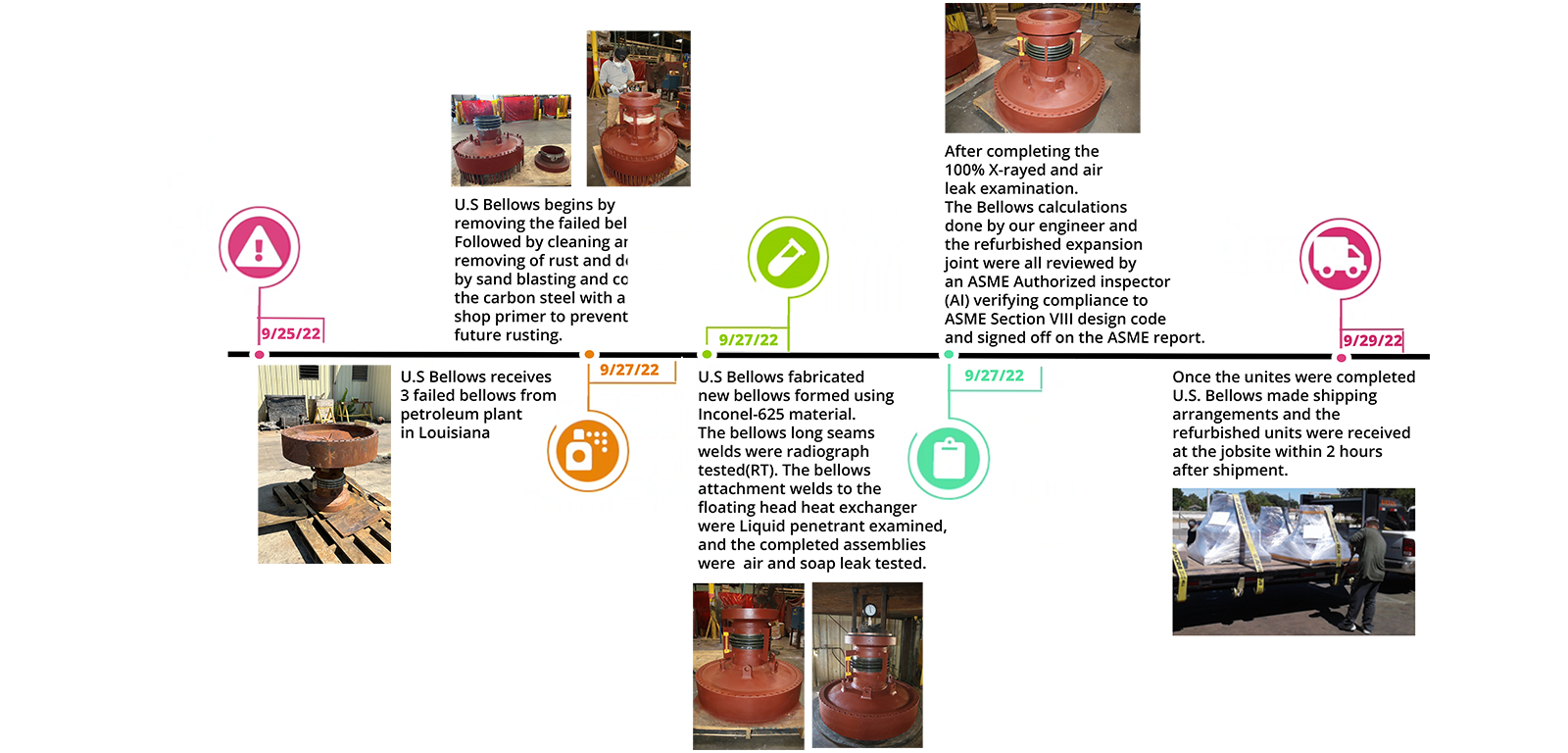

US Bellows knows things don’t always go as planned during a Turnaround (TA). If you find a leaking bellows during a TA inspection, US Bellows has replaced expansion joints in just 2 days after receiving the exchanger. It doesn’t matter if it’s during the week or weekend US Bellows will work with you to make sure you meet your deadlines.

US Bellows also offers on-site services, including inspection, installation supervision, and repair of both metal and fabric expansion joints. Our expertise extends to unique challenges and repairs such as the “Clamshell” Bellows Replacement Method, ensuring minimal down time and optimal system performance. US Bellows holds an R-stamp in addition to our U-stamp for coded vessels.

Heat exchangers require specialized expansion joints to handle thermal expansion, vibration, and high-pressure environments. Our bellows, made from SA and SB-grade materials, are engineered to accommodate a wide range of operating temperatures and pressures, ensuring seamless integration with shell-and-tube heat exchangers.

Using U-shaped convolutions, our expansion joints are built to handle extreme thermal cycles while maintaining system efficiency. We employ ASME-qualified welders and precision manufacturing techniques to deliver durable and long-lasting products.

- Key Features of US Bellows Products:

- Pressure Range: From full vacuum to 2,000 PSIG.

- Temperature Range: Operating safely up to 1,500°F.

- Sizes: Metal expansion joints from 2” to 180” and custom rectangular designs of any practical size.

- Material Options: All 300 series stainless steels and Corrosion-resistant and high-strength nickel alloys to meet diverse application needs.

- Industries We Serve

Our expansion joints are trusted across various industries, including:

- Refining

- Power Generation

- Chemical Processing

- Marine and Offshore

- Pipeline Systems

- Nuclear

When it comes to maintaining the reliability and efficiency of your heat exchangers, trust US Bellows to deliver ASME Section VIII-certified, U-stamped expansion joints tailored to your exact requirements. Contact us today to learn more or request a custom quote for your next project.