Understanding how metallic bellows move and deflect is crucial for the design and safety of any piping system. Bellows, which are the flexible core of an expansion joint, are specifically engineered to accommodate various types of movement caused by factors like thermal expansion, pressure fluctuations, and equipment vibration. A proper understanding of these movements: axial, lateral, angular, torsional, combined, and cyclic, allows engineers to select and apply expansion joints to ensure the system’s lifespan is correct. Misunderstanding these deflection types can lead to bellows fatigue, premature failure, and catastrophic system damage.

Axial / Lateral / Angular / Torsional / Combined / Cyclic – with In-depth Technical Explanations

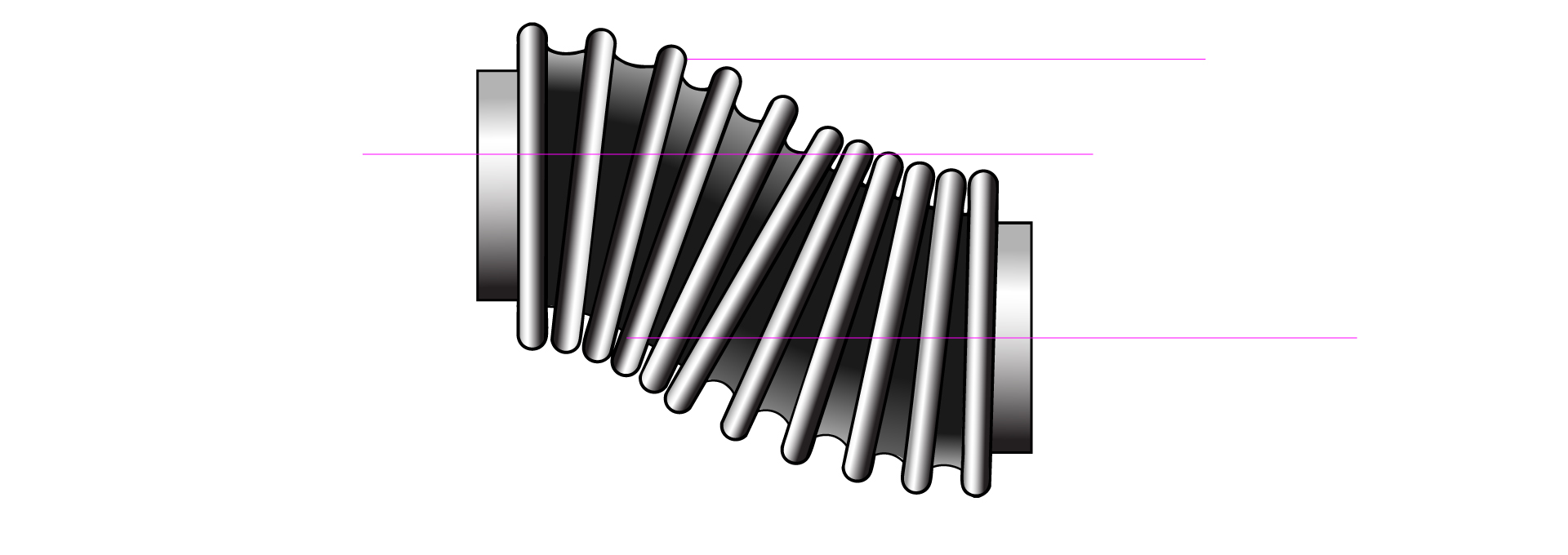

Axial deflection is the change in the length of a bellows along its longitudinal axis. It can occur as either compression (shortening) or extension (elongation). This movement is a primary function of most expansion joints and is directly related to the thermal expansion or contraction of a piping system. The spring rate of a bellows, measured in force per unit of axial deflection, determines the force required to compress or extend it. Designers must carefully calculate the necessary axial deflection to ensure the bellows operates within its specified limits.

Lateral deflection, also known as transverse deflection, is the sideways movement of one end of the bellows relative to the other, perpendicular to its centerline. This movement is often caused by lateral pipe displacement or offset misalignment. While bellows can handle some degree of lateral movement, it introduces bending stresses on the bellows convolutions, which must be accounted for in the design. The lateral spring rate, expressed as force per unit of lateral displacement, is used to calculate the forces exerted on adjacent equipment and anchors.

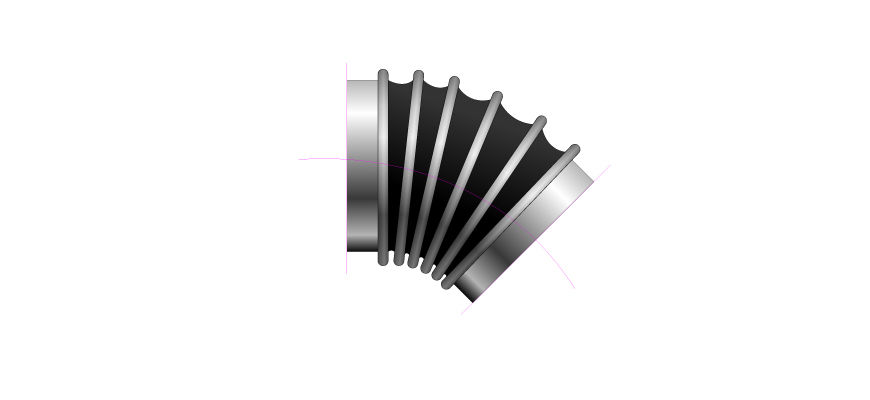

Angular deflection is the rotational movement of a bellows, where one end pivots relative to the other, causing the bellows to bend. This movement is typically managed by hinged or gimbal expansion joints. Angular deflection introduces bending moments on the bellows and is often caused by pipe rotation or an unequal thermal expansion of parallel pipes. The angular spring rate, measured in moment per degree of rotation (e.g., lb-in/degree or N-m/degree), is used to calculate the forces on the piping system.

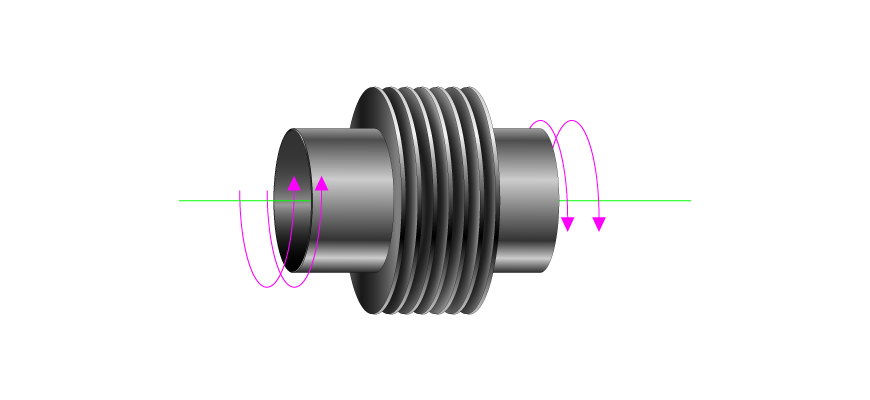

Torsional deflection is the twisting of a bellows around its longitudinal axis. Metallic bellows are generally not designed to accommodate torsional loads. This type of movement can cause significant stress concentrations, leading to rapid fatigue failure. Therefore, system designers must employ proper pipe routing and anchoring to prevent torsional forces from being applied to the expansion joint. Designers must apply EJMA and ASME standards to calculate deflection ratings correctly.

Combined deflection occurs when a bellows is subjected to two or more types of movement simultaneously, such as a combination of axial and lateral deflection. This is a common occurrence in real-world piping systems. The cumulative effect of these movements can be complex to calculate. When designing for combined movement, engineers must ensure that the total stress from all deflection types remains below the material’s fatigue limit.

Cyclic deflection refers to repeated movements that the bellows experiences over its operational life. The number of cycles a bellows can withstand before fatigue failure is its cycle life. This is a critical design parameter, as it directly impacts the longevity of the expansion joint. Movements caused by thermal cycling, pressure changes, and vibrations are all considered cyclic. The required cycle life must be specified during the design phase, as it affects the bellows’ overall geometry and material thickness.

Talk to our engineers for bellows-specific recommendations.

Did you know that US Bellows is a Piping Technology Company?

We are proud to be a one-stop solution from expansion joints to pipe supports and engineering services. We work hard to simplify your supply chain and ensure system reliability with quality assurance.