Features

- Eliminates pressure instability

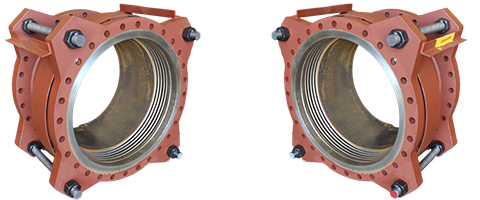

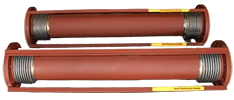

- Good for large axial compression or extension

Technical Information

Installation & Maintenance (Metallic Expansion Joints)

Diagram of a Refractory Lined Expansion Joint

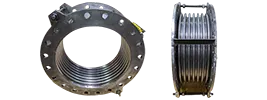

Types of Metallic Bellows Deflections

Bellows Expansion Joint Loads

How to Look for Signs of Expansion Joint Failure

View more Technical Information

FAQs

How to Test an Expansion Joint?

How do metallic bellows function?

Case Studies

2/1/15: 84″ Dia. Refractory Lined Universal Expansion Joint Designed for an FCC Unit

4/14/13: Refractory Lined Expansion Joint Designed for a Clean Fuels Project

5/2/03: Refractory-lined Expansion Joint for an FFC Unit in India

Request A Quote