metallic-expansion-joints

Yes, hinged expansion joints do need to be designed to accommodate for pressure thrust.

Expansion joints have one loose flange when specified to facilitate the alignment of flanges on the piping system during installation.

We do not recommend the annealing of stainless steel bellows because the bellows strength increases while decreasing the cycle life.

Metallic expansion joints should be replaced if they are leaking or can simply be replaced on a scheduled maintenance program in order to avoid leaks that may occur in the future.

We get inquiries for steel and rubber expansion joints for pump suction and discharge.

If bellow thickness is increased, then the bellows spring rate will increase substantially.

Unreinforced bellows do not have any external type of reinforcement such as root rings or equalizing rings.

The gimbal expansion joint is basically the same as the hinge type, except that instead of being limited to deflection in only one plane, it can accept bending or angulation in any plane. It contains two sets of hinge pins or pivots, the axis of each set perpendicular to the other. Each set of pins is connected to each other with a central gimbal ring, in much the same way that a universal joint on an automobile works.

Expansion joint thickness can vary from .010 inches to .125 inches thick depending upon the design requirements for your application.

The effective diameter of the bellows is the mean diameter of the convolutions.

A pressure balanced expansion joint is a combination of several types of expansion joints. Its purpose is to retain and balance the pressure thrust so that main anchoring of the pipe or adjacent equipment is not required, and forces and movements on attachment flanges of delicate equipment, such as turbines, are kept to acceptably low levels.

Why are pressure balanced expansion joints used?

A piping system typically requires pressure-balanced expansion joints because axial deflections are also present. In order to accept these movements, a bellows is added beyond the elbow with the same cross-sectional area as the ones in the universal section.

This balancing bellows is connected by the tie rods to the pipe beyond the universal section; in this way, the pressure thrust is contained as tension in the tie rods. The section of the expansion joint between the tie rods, which includes the elbow, is now free to move axially, with the only resistance being a function of the spring rates of the bellows.

Because of their arrangement, however, the spring rate of the entire expansion joint is the sum of the spring rates of the balancing and the universal bellows. This is a constant volume system, in that when the universal end compresses, the balancing end extends the same amount. All of the lateral deflection is absorbed by the universal end, and there is no lateral deflection imposed on the balancing end. Therefore, the balancing bellows is almost always a single bellows type.

Looking for pressure balanced expansion joints? Visit our product page or speak with an engineer to know exactly what you need.

Did you know that US Bellows is a Piping Technology Company?

We are proud to be a one-stop solution from expansion joints to pipe supports and engineering services. We work hard to simplify your supply chain, and ensure system reliability with quality assurance.

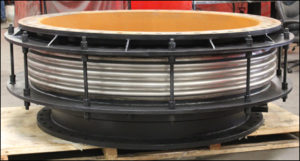

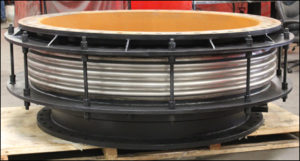

A metallic expansion joint device is used to absorb thermal movement. It is generally fabricated from stainless steel or other high nickel alloys.

We typically only use carbon steel material for the bellows rectangular expansion joints which are installed in duct systems. Round expansion joints don’t typically have carbon steel bellows, however for both round and rectangular expansion joints, the flanges, pipe, and hardware may be carbon steel.

Flanged and flued expansion joints can take minimal amounts of axial motion due to the thickness of the flanged and flued heads.

The flange on an expansion joint can be one of the end connections to allow for connection to the pipe in the piping system.

Ply refers to the number of sheet metal thicknesses used in the forming of the bellows. Therefore, a 2-ply bellows would be composed of two sheets of metal.

Heat exchanger shell bellows are used on fixed tube sheet heat exchangers. Bellows deflection is only axial and can be either extension or compression depending on the differential expansion of shell and tubes. In most cases the tubes are hotter than the shell, moreover tube material is sometimes high alloy, i.e. Stainless steel or nickel alloy, which expands about 50% more than carbon steel.