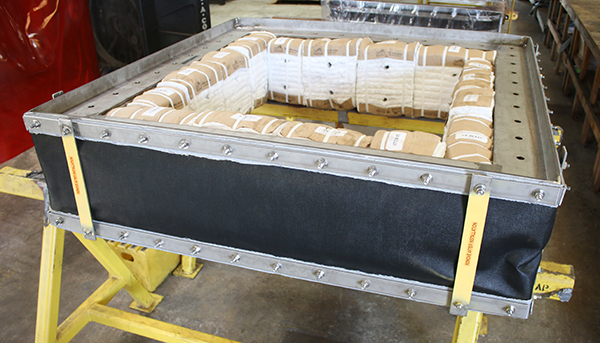

| Type: | Fabric Expansion Joint |

| Size: | 20″ Diameter & 18″ Length |

| Material: | 1-Ply PTFE Fabric Belt/Carbon Steel Framework |

| Design: | -20°F/+600°F with a +/- 20″ Water Column, and +/- 1″ of Axial Compression & Lateral Offset |

| Testing: | 100% Dye-Penetrant |

U.S Bellows fabricated these fabric expansion joints for a carbon gas application at an oil and gas facility in Louisiana. These units are 20″ in diameter and 18" in length. The 1-ply fabric belt is made from PTFE, and the framework is carbon steel. They are designed for an operating temperature of -20°F/+600°F with a +/- 20" water column and +/- 1" of axial compression and lateral offset. The welds of the units were dye penetrant tested prior to shipment.

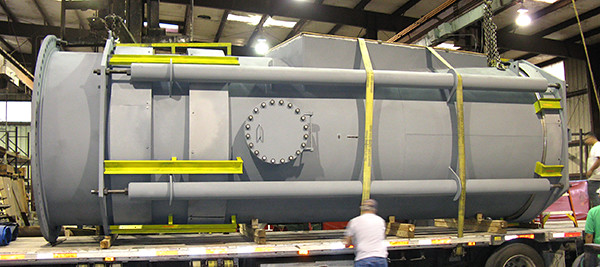

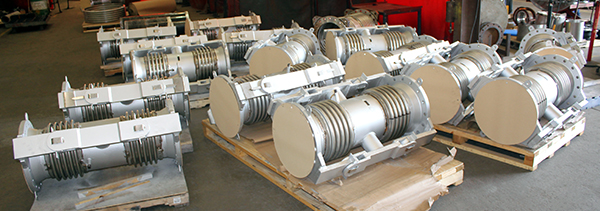

US Bellows and its subsidiaries have served as leading global suppliers of carbon black worldwide. Material from these plants is made to exacting standards for tires, coatings, ink, batteries, plastics, and numerous other specialty high-performance applications. Carbon black is produced from the thermal decomposition of heavy petroleum raw materials, such as coal tar, ethylene cracking tar, or FCC tar. It is widely utilized owing to its various beneficial characteristics, including surging tire tread wear and rolling resistance, effectively absorbing ultraviolet (UV) light and converting it into heat, improved thermal conductivity, and superior UV protection. Several processes, such as oil furnaces and thermal, are mainly used to manufacture carbon black. In addition to providing expansion joints, we have provided the following products from our portfolio of manufactured in our facility in Houston, Texas:

- Constant Spring Hangers

- Metallic Expansion Joints

- Pipe Shoes, Guides, and Anchors

- Insulated Supports

- Paddle Blinds and Spacers

- Pipe Hangers Hardware

- Slide Bearing Plates

- Instrument Supports

- Variable Spring Hangers

PT&P REF. ORIGINAL POST 08122017