Details:

|

Design Conditions:

|

Resources

Resources

54″ Pressure Balanced Elbow Turbine Crossover Expansion Joints for a Power Generation Plant

U.S Bellows, Inc. refurbished two pressure balanced elbow expansion joints for a power generation plant with a quick turnaround during outages.

The first 54″ outside diameter expansion joint leaked from a crack in the bellows causing an unscheduled power plant outage.

This particular expansion joint was fabricated for a high pressure turbine crossover piping for steam service of 97 PSIG at 634°F. The 27′ long, 27,000 lb. expansion joint was refurbished in less than 4 weeks. This was made possible by utilizing dedicated employees working overtime 6 days a week. The 321 stainless steel bellows and carbon steel root rings were replaced. The outside cover bolts were removed and new bolts were installed.

The second expansion joint was also for a high pressure turbine that was replaced during a planned outage. This expansion joint came in on October 30, 2006 and was ready to ship November 20, 2006. Overall length and center line to center line length were maintained to ensure easy installation. Both expansion joints were dye-penetrant tested and hydro-tested at 146 PSIG.

U.S. Bellows, Inc. Designed and Fabricated Flange Expansion Joints for a Thermal Power Plant

|

Tied Universal Expansion Joint for Pipe Carrying Sulfur Dioxide

This tied universal expansion joint is designed to carry hot gas up to temperatures of 1022°F and pressure up to 5 PSIG. It has a 66″ inside diameter and is 72″ in overall length. The design movements are 4″ lateral and 4.5″ axial compression. The bellows’ material is Inconel® 825 with carbon steel weld ends. The bellows and pipe longitudinal weld seams were 100% x-rayed prior to a 5 PSIG air test and then dye-penetrant examined after testing.

U.S. Bellows, Inc. Designed and Fabricated Expansion Joints that Required Helium Leak Testing

|

||

|

This order required custom engineering to design and manufacture these expansion joints due to their critical service condition requirements. PT&P manufactured and tested these expansion joints to the customer specifications, EJMA Standards, and US Bellows Quality Standards.

Design Condition:

| 176 PSIG at 500°F | |

| 0.5 Axial Extension and 1.5 Axial Compression | |

| 18″ 304 Stainless Steel Expansion Joints with Special Designed and Machined Flange Faces with a Specially Designed Gasket Groove | |

| Special Customer Welding Requirements to A.W.S. Standards | |

| Critical Spring Rate Requirements | |

| Stringent Testing Requirements | |

| The Bellows Longitudinal Seams were 100% X-Rayed and Dye-Penetrant Examined. | |

| Each Expansion Joint was Helium Leak Tested to a Leak Rate of 1 x 10 ֿ 7 |

Metallic Universal Expansion Joints for a Wisconsin Chemical Plant’s Emergency Shut Down

A customer’s existing expansion joint failed and caused a plant to shut down. They required an immediate replacement joint. This universal expansion joint order was placed, designed, and fabricated in just one day. The order came in at 8:30 am on Saturday, Labor Day weekend, and was shipped at 4:00 pm, which minimized the time of the plant shut down. This universal expansion joint is 96″ in overall length, 20″ inside diameter, and can absorb 3.25″ lateral movement. A 100% dye-penetration test and a hydro-test were performed to ensure quality.

|

|

Tied Universal Expansion Joints for an Engineering and Construction Company

These pictures display one of many tied universal expansion joints in a large order of expansion joints designed by U.S. Bellows, Inc. for a local engineering and construction company. These expansion joints weigh 1,600 lb. each and are 10″ in diameter. They are designed for 611 PSIG and temperatures up to 180°F. These expansion joints are fabricated from 321 carbon steel pipe, tie rods and 300 lb. RF weld neck flanges. The bellows longitudinal seams were 100% x-rayed and the complete assembly was hydro-tested to 917 PSIG to ensure a quality product and performance. The units were shipped with the mating flanges bolted to the end of the assembly.

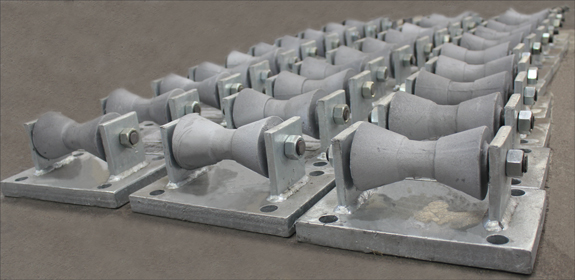

Can you use insulated piping on pipe rollers? Would the insulation be crushed?

In order to use pipe rollers in this application, an insulated pipe support has to manufacture as part of the roller assembly. We use a higher density insulation so that the insulation will not be crushed – 10 lb.14 lb. 20 lb. or 32 lb. depending on the load.

Eight Polyurethane Pipe Rollers for a Gas Plant

Two Expansion Joints for an Air Intake on a Generator Unit at a Packaged Power facility in Houston.

|

|

These 59″ x 39.5″ fabric expansion joints were fabricated using a 1/8″ thick neoprene sheet. The joints were then bonded to the carbon steel angles and plates, and secured using stainless steel band clamps, with T-bolt latches. The carbon steel angles and plates were primed and finished at U.S. Bellows, Inc.’s paint production facility. |

The expansion joints were designed to facilitate any vibration and movement during the generator units’ normal operation.

60″ Ductwork with Spring Supports, Snubbers, a Support Cradle and a Fabric Expansion Joint

U.S. Bellows, Inc. and PT&P combined to furnish a fabric expansion joint, duct work, a spring support cradle and snubbers. US Bellows furnished a fabric expansion joint with acid resisting fabric and also a duct work measuring 34″ long and 60″ in diameter which was fabricated from ASTM A 516GR 70 carbon steel. PT&P furnished spring supports, carbon steel cradle supports, and snubbers. The expansion joint was completed within 6 weeks in time for a plant shutdown. A computerized pipe stress analysis, utilizing the Caesar II stress program, was performed to obtain the forces and moments imposed on the equipment nozzles and weights to be carried by the spring supports.

U.S. Bellows, Inc. Designed and Fabricated 15 Expansion Joints for a Power Generation Company in Wisconsin PT&P#80396

|

These 15 pressure relief safety valve connector expansion joints were manufactured from 316SS, A-335 P22, A-387 Gr22, A106, and A-51670. They were externally pressurized to prevent steam blowback. These externally pressurized expansion joints were attached to the relief valves in the power plant. They assist in maintaining pressure as well as provide for 7 axial and 6 lateral travel. These joints can handle applicable loads of up to 150 PSIG at 535°F and 460 PSIG at 885°F but can function if temperatures reach 1,000°F. They range from 30″ to 85″ in length and weigh between 400 lbs and 1,600 lbs. Dye penetrate, air, and soap bubble tests were completed for quality and performance assurance. |

U.S. Bellows, Inc. Fabricated and Designed 5 Expansion Joints for a Heat Exchanger Company in Japan

|

These single expansion joints were fabricated from ASTM-A-240 Type 321 stainless steel bellows and liners. The shell material is ASTM-A-516 Grade 70. They are 32 diameters with an overall length of 26″. Each joint weighs 280 lbs. They were designed for 150 PSIG at 650F with a travel capacity of 0.33″ axial compression and 0.08″ lateral deflection. These expansion joints absorb differential expansion between the shell side and the tube side of a heat exchanger. |

They were hydrostatically tested to 208 PSIG to comply with the Japanese code, Ministry of Health, Labor and Welfares (MHLW), and the ASME Pressure Vessel Code Section VIII

Two Fabric Expansion Joints for an Oil Refinery in Saudi Arabia

These are 24″ diameter fabric expansion joints with an overall face to face dimension of 12″. Each expansion joint weighs 300 lb. Installed in the inlet and exhaust piping of a hot air blower, they can withstand temperatures of up to 850°F. These expansion joints were fabricated in three layers that consisted of aluminized fiberglass, ceramic fiber, and silica treated fabrics. The flanges were fabricated from carbon steel with special hex nuts welded to the inside of the bolt holes. The stud bolts are in place to assure correct alignment of the bolts to the flange bolt holes. Visual inspection and trial fitting of the stud bolts were performed to assure quality and performance.

These are 24″ diameter fabric expansion joints with an overall face to face dimension of 12″. Each expansion joint weighs 300 lb. Installed in the inlet and exhaust piping of a hot air blower, they can withstand temperatures of up to 850°F. These expansion joints were fabricated in three layers that consisted of aluminized fiberglass, ceramic fiber, and silica treated fabrics. The flanges were fabricated from carbon steel with special hex nuts welded to the inside of the bolt holes. The stud bolts are in place to assure correct alignment of the bolts to the flange bolt holes. Visual inspection and trial fitting of the stud bolts were performed to assure quality and performance.

U.S. Bellows, Inc. Designed and Fabricated a Single Expansion Joint Assembly for an Oil Refinery in South Africa

This single expansion joint assembly was fabricated with a single-ply 304 stainless steel bellows, and carbon steel pipe, miter bends, and limit rods. It measured 12′-2″ from the center to center of the elbows. These bellows were designed with a low spring rate to meet the allowable forces and movements on the compressor inlet nozzle. All welds were air tested and spot x-rayed to assure quality and performance. This unit was completed in 3 weeks to meet the customer’s construction schedule.

U.S. Bellows, Inc. Designed and Fabricated a Single Reinforced Expansion Joint for an Oil Refinery in Saudi Arabia

| This single reinforced expansion joint is 16″ in diameter and is 15-1/8″ in length. The expansion joint is fabricated with 316L stainless steel bellows, liner, weld ends, and bellows reinforcement. This expansion joint weighs 170 lbs and is used in a feed pre-heater. It is designed and fabricated to ASME Section VIII for 581 PSIG at 842°F with a travel capacity of 0.496″ compression. 100% Dye-Penetrate testing was performed for the bellow attachment welds as well as 100% X-Ray testing on the long seam welds of the bellows and pipe ends. In addition, Hydro-testing was performed at 764 PSIG to assure quality and performance. |