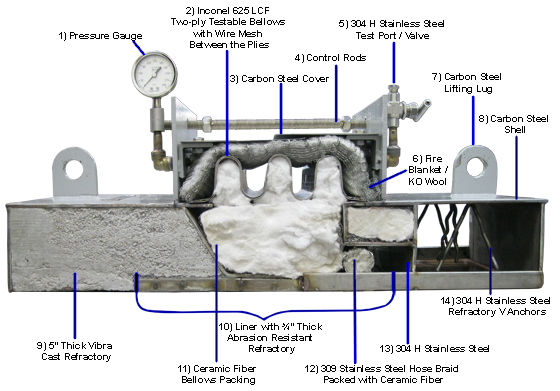

- Pressure Gauge – to monitor the pressure between the plies

- Inconel 625 LCF Two-ply Testable Bellows with Wire Mesh between the Plies – the wire mesh ensures flow from one side to the other side across the convolutions

- Carbon Steel Cover – pressure sealing in the even of bellows leak

- Control Rods – limits thermal movement

- 304 Stainless Steel Test Port / Valve – connection for air test of bellows

- Fire Blanket / KO Wool – keeps the bellows temperature above the dew point temperature of the flue gas (350°F to 450°F)

- Carbon Steel Lifting Lug – facilitates lifting

- Carbon Steel Shell

- 5″ Thick Vibra Cast Refractory – reduces shell temperature to 350°F

- 3/8″ Thick 304 Stainless Steel Liner with 3/4″ Thick Abrasion Resistant Refractory

- Ceramic Fiber Bellows Packing – reduces bellows temperature to under 1000°F

- 309 Stainless Steel Hose Braid Packed with Ceramic Fiber – seals the liner gap to prevent the catalyst from collecting in the bellows

- 304 H Stainless Steel – insulation box

- 304 H Stainless Steel Refractory V Anchors – secures refractory to pipe