Understanding your pipe expansion joint model number is essential for identifying the exact specifications of your product.

What Our Expansion Joint Model Number Tells You

At US Bellows, we manufacture hundreds of thousands of expansion joints annually, each with a unique combination of diameter, length, type, material, pressure rating, and other specific features.

To ensure accuracy in manufacturing, installation, and future repairs, every expansion joint we produce is clearly labeled with a standardized model number. This code makes it easy for engineers, maintenance teams, and procurement managers to quickly verify the product’s design details.

How to Read a Pipe Expansion Joint Model Number

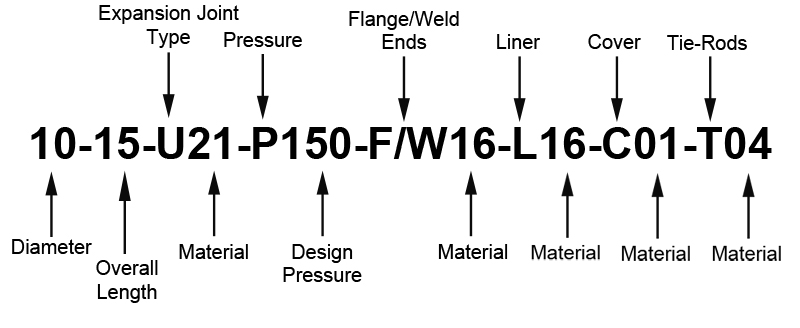

A pipe expansion joint model number is more than just a label, it’s a precise code that tells you everything about the expansion joint’s specifications.

Each part of the model number corresponds to a specific detail, including diameter, length, material, type, and pressure rating. This ensures that the correct joint is manufactured, installed, and maintained for your application.

The example below shows how a model number is broken down:

Why the Model Number Matters

Having a clear pipe expansion joint model number helps with:

- Standardization: Every joint follows a consistent identification system.

- Maintenance & Repairs: Technicians can easily identify replacement parts.

- Engineering Accuracy: Ensures the correct joint is installed for the design pressure, movement, and environmental conditions.

- Faster Communication: Reduces errors when ordering, manufacturing, or servicing joints.

Expansion Joint Model Number Description

Below are the most common sections you will see in a pipe expansion joint model number:

1. Diameter: Nominal pipe size, usually in inches.

2. Overall Length: Total joint length from end to end.

3. Expansion Joint Type: Style designation (e.g., single, universal, hinged).

| S | Single | FABRIC | Fabric |

| U | Universal | REC | Rectangular |

| XS | Single X-Flex | REC_S | Single Rectangular |

| XD | Dual X-Flex | REC_U | Universal Rectangular |

| HIN | Hinged | EPB | Elbow Pressure Balanced |

| HIN_S | Single Hinged | PBI | Pressure Balanced In-Line |

| HIN_U | Universal Hinged | F&F | Flanged & Flued |

| GIM | Gimbal | REFR | Refractory Lined |

| GIM_S | Single Gimbal | SLIP | Slip Type |

| GIM_U | Universal Gimbal | RUB | Rubber |

4. Material: Specifies the expansion joint material.

| Carbon Steel | 01 |

| 304 Stainless Steel | 04 |

| 316 Stainless Steel | 16 |

| 321 Stainless Steel | 21 |

| Hastelloy | 27 |

| Inconel® 600 | 60 |

| Inconel® 800 | 80 |

| Inconel® 825 | 82 |

| Duplex 2205 | 2205 |

| Fabric | 97 |

| Rubber | 98 |

5. Design Pressure: The pressure rating in pounds per square inch (psi).

6. Flange/Weld Ends: End connection type on an expansion joint, welded or flanged. (Also available in Vanstone (V) or Special (X) styles)

7. The material of the flanges or weld ends.

|

Flange Ends

|

Weld Ends

|

Material

|

| F01 | W01 | Carbon Steel |

| F04 – F04H – F04L | W04 – W04H – W04L | 304 stainless steel |

| F16 – F16H – F16L | W16 – W16H – W16L | 316 stainless steel |

| F21 – F21H – F21L | W21 – W21H – W21L | 321 stainless steel |

| F309 | W30 | 309 stainless steel |

| F600 | W60 | Inconel 600 |

| F625 | W62 | Inconel 625 |

| F800 | W80 | Inconel 800 |

| F825 | W82 | Inconel 825 |

| F2205 | W2205 | Duplex 2205 |

Accessories:

8. Liner Material (if included): Protects the bellows from flow media and vibration.

|

Liner

|

Material

|

| L01 | Carbon Steel |

| L04 – L04H – L04L | 304 stainless steel |

| L16 – L16H – L16L | 316 stainless steel |

| L21 – L21H – L21L | 321 stainless steel |

| L309 | 309 stainless steel |

9. Cover Material: Protects the bellows externally from damage.

|

Cover

|

Material

|

| C01 | Carbon Steel |

| C04 – C04H – C04L | 304 stainless steel |

| C16 – C16H – C16L | 316 stainless steel |

| C21 – C21H – C21L | 321 stainless steel |

| C309 | 309 stainless steel |

10. Tie-Rods: Restrains pressure thrust or controls movement.

|

Tie Rods

|

Material

|

| T01 | Carbon Steel |

| T04 – T04H – T04L | 304 stainless steel |

| T16 – T16H – T16L | 316 stainless steel |

| T21 – T21H – T21L | 321 stainless steel |

| T309 | 309 stainless steel |

Other items that, if ordered, will also be included in the product model number: Root Rings, Equalizing Rings, and In the case of a Gimbal Pipe Expansion Joint, a box is specified, and the material

11. Root Rings: Provides internal reinforcement at the weld ends.

|

Box

|

Material

|

| R01 | Carbon Steel |

| R04 – R04H – R04L | 304 stainless steel |

| R16 – R16H – R16L | 316 stainless steel |

| R21 – R21H – R21L | 321 stainless steel |

| R309 | 309 stainless steel |

12. Equalizing Rings: Distributes internal pressure evenly across the convolutions.

|

Box

|

Material

|

| E01 | Carbon Steel |

| E04 – E04H – E04L | 304 stainless steel |

| E16 – E16H – E16L | 316 stainless steel |

| E21 – E21H – E21L | 321 stainless steel |

| E309 | 309 stainless steel |

13. In the case of a Gimbal Pipe Expansion Joint, a box is specified, and the material

|

Box

|

Material

|

| B01 | Carbon Steel |

| B04 – B04H – B04L | 304 stainless steel |

| B16 – B16H – B16L | 316 stainless steel |

| B21 – B21H – B21L | 321 stainless steel |

| B309 | 309 stainless steel |

How to Use This Guide

When you read the pipe expansion joint model number printed on your product:

- Match Each Section: Compare the code with the corresponding descriptions in the chart.

- Refer to Material Tables: Use our reference tables to decode material numbers (e.g., stainless steel, carbon steel).

- Confirm Your Specifications: Ensure the expansion joint matches your engineering and operational requirements.

By understanding your pipe expansion joint model number, you can streamline maintenance, reduce downtime, and ensure you’re working with the correct product.

Did you know that US Bellows is a Piping Technology Company?

We are proud to be a one-stop solution from expansion joints to pipe supports and engineering services. We work hard to simplify your supply chain, and ensure system reliability with quality assurance.