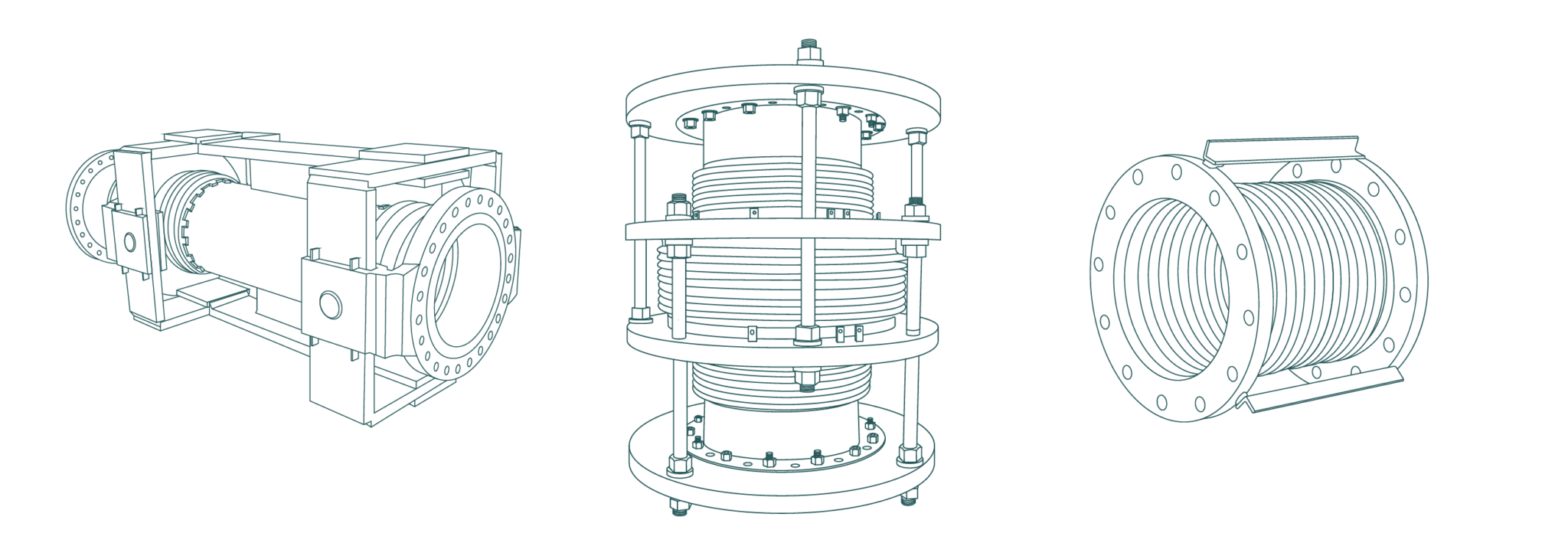

Metallic bellows, also known as metal bellows or metal expansion joints, are engineered flexible metal tubes designed with multiple convolutions for both flexibility and sealing.

They absorb movement, vibration, and thermal expansion in countless industrial applications. You’ll find them everywhere, from tiny instruments to huge piping systems, always quietly doing their job of keeping things flexible and sealed up tight.

What are Metallic Bellows?

Metallic bellows are flexible, thin-walled metal components characterized by a series of parallel folds or convolutions. These convolutions allow the bellows to extend, compress, and bend, accommodating dynamic changes within a system while maintaining a hermetic, tight seal.

They are typically manufactured from ductile metals, such as stainless steel, nickel alloys, and titanium, which are chosen for their durability, corrosion resistance, and ability to withstand extreme temperatures and pressures.

How Metallic Bellows Work

The unique flexibility of metal bellows stems from their corrugated, folded design. When they’re pushed, pulled, or bent (engineers call this axial, lateral, or angular movement), these convolutions deform elastically, distributing stress evenly across the entire material.

This allows them to absorb significant displacement without compromising their structural integrity or sealing capabilities.

The number of convolutions, their depth, and the material thickness are all carefully calculated during the bellows design phase to achieve the desired spring rate, movement capacity, pressure rating, and cycle life for specific applications.

How We Manufacture Metallic Bellows

The manufacturing process significantly influences the characteristics and applications of different types of metallic expansion joints:

Punch-Forming (or Expansion-Forming) is cost-effective for high-volume production, offers moderate flexibility, are ideal for applications like expansion joints in piping systems, petrochemical refineries, and power plants.

Key Advantages of Metallic Bellows

The widespread adoption of metallic bellows across diverse industries is proof of the value they deliver, including:

- Exceptional Flexibility: They effectively absorb axial, lateral, and angular movements, preventing stress on rigid components.

- Hermetic Sealing: Their precisely welded construction ensures leak-tight operation, which is crucial for vacuum applications, fluid transfer, and the containment of hazardous media.

- Vibration Damping: Metal bellows excel in applications with high-frequency and low-amplitude vibrations, preventing fatigue damage to adjacent machinery and piping.

- However, vibrations from reciprocating machines (low frequency and high amplitude) will cause harm to the metal bellows. Pressure pulsing vibrations can not be dampened by metal bellows. In applications like these, we recommend using other vibration isolators and dampeners on the line, such as anchors, covers, and pads.

- Thermal Expansion Compensation: They readily accommodate changes in length caused by temperature fluctuations, protecting pipelines and equipment from thermal stress.

- High Reliability and Durability: When properly designed and manufactured from suitable materials, metallic bellows offer a long service life, even in extreme environments, thereby reducing maintenance and downtime.

- Corrosion Resistance: Available in various alloys, they can withstand corrosive substances and harsh industrial conditions.

- Precision Movement Control: Essential for sensitive instruments, robotics, and aerospace applications that require precise adjustments.

Selecting the Right Bellows for Your Project’s Needs

Proper selection and installation are crucial for the long-term performance of metallic bellows. Factors to consider include:

- Application type: What type of facility, equipment, and media will be used for the metallic bellows?

- Operating Conditions: Temperature, pressure, and the nature of the media (such as corrosive or abrasive) significantly influence material selection and design.

- Movement Requirements: The type and magnitude of anticipated axial, lateral, and angular movements dictate the bellows’ design and convolution profile.

- Cycle Life: The expected number of flex cycles is a critical factor in determining the bellows’ material and wall thickness.

- Material Compatibility: Ensuring the bellows material is compatible with the conveyed media prevents corrosion and premature failure.

- Installation Practices: Correct installation, including proper alignment and anchoring, is vital to prevent overextension, over-compression, and premature fatigue.

Applications Across Industries

| Market | Key Applications |

| Power Generation | Steam lines, HRSGs, FGD ducts, turbine exhaust, air preheaters, stacks |

| Petrochemical & Refining | FCCU lines, fired heaters, oxidizers, flare lines, reactor piping |

| Chemical Processing | Corrosive media piping, heat exchangers, scrubbers, reactor headers |

| Cement, Steel, and Mining | Kiln ducts, clinker cooler, ESPs, fans, combustion air ducts |

| Pulp & Paper | Recovery boiler ducts, kiln exhaust, black liquor units, stacks |

| Marine & Offshore | Engine exhausts, seawater cooling, ballast piping, diesel generator lines |

| HVAC, Utility & District Energy | Steam/chilled water piping, underground lines, pumps, exchangers |

| Nuclear Power | Reactor coolant systems, steam generators, safety relief piping, air handling ducts |

| Semiconductor Manufacturing | Ultra-pure water systems, exhaust ducts, vibration isolation for precision tools |

| Electric Vehicle (EV) Manufacturing | Battery line cooling systems, HVAC, test station piping, compressed air lines |

| Data Centers | Chilled water piping, thermal expansion in raised floors, generator exhaust, HVAC systems |

Why Choose US Bellows for Your Expansion Joints

With over 4,500 expansion joints shipped last year, US Bellows combines unmatched expertise with advanced manufacturing capabilities.

Our dedicated industrial engineering team streamlines production using digital work instructions and specialized processes for welding thin-gauge superalloys.

Backed by Piping Technology’s large-scale operation, we can quickly scale output with cross-trained welders and support teams to meet demanding schedules. Every joint is built under rigorous quality control, ensuring long-lasting performance and reliability in the toughest applications.

Ready to get started?

Get detailed specifications, material options, and design guidelines for our full line of metallic bellows and expansion joints. Download the US Bellows catalog today and find the right solution for your next project.