Features

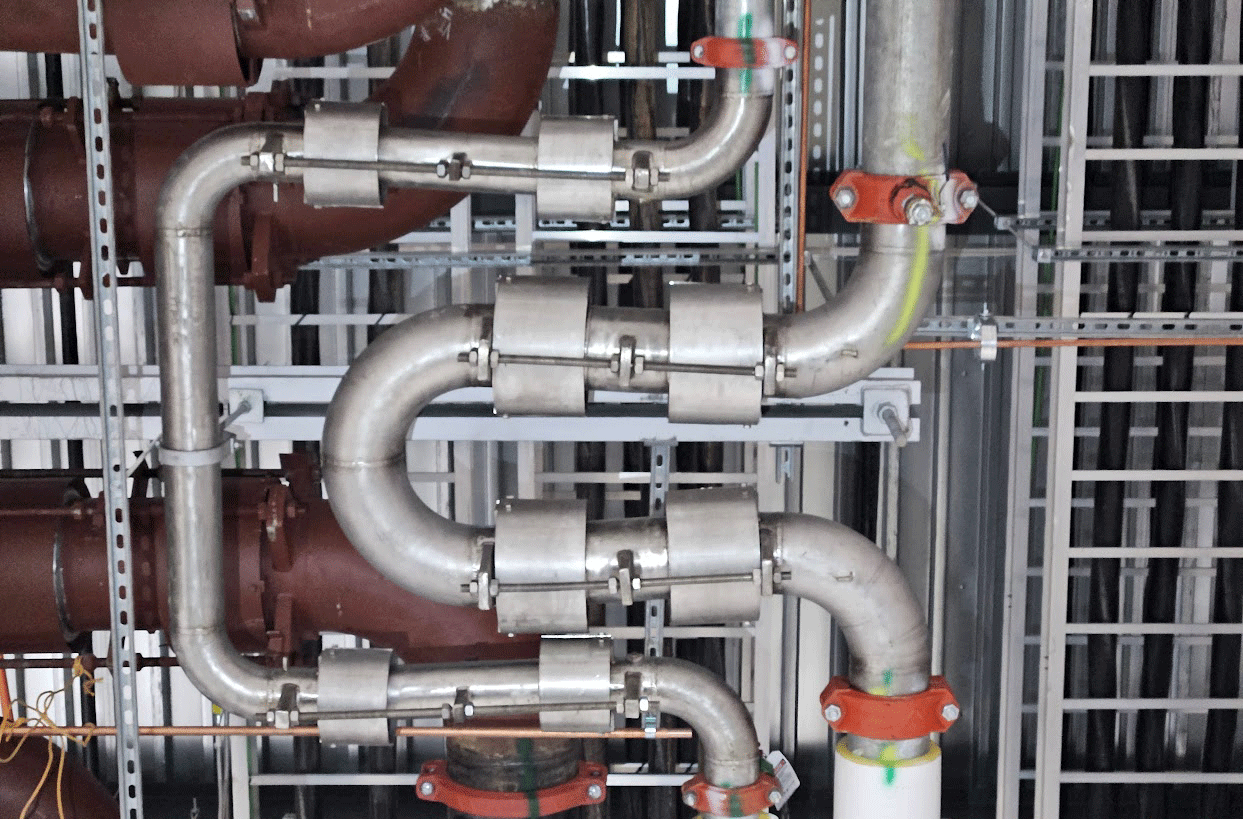

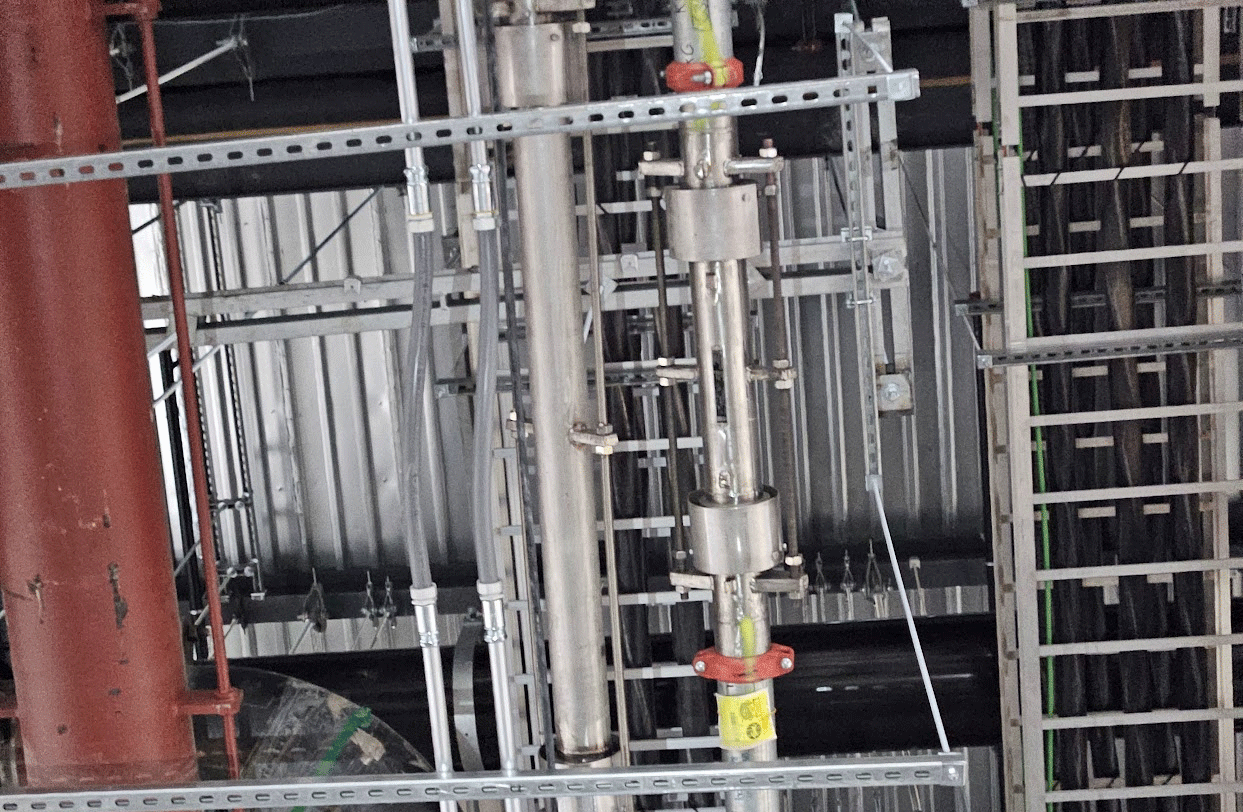

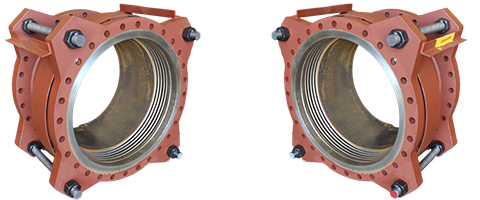

- Industry-First Hybrid Design: We are the first manufacturer to build U-loops with bellows integrated into the loop structure. This hybrid approach provides superior flexibility for both thermal expansion and seismic movement without compromising the pressure rating or overall design of the piping system.

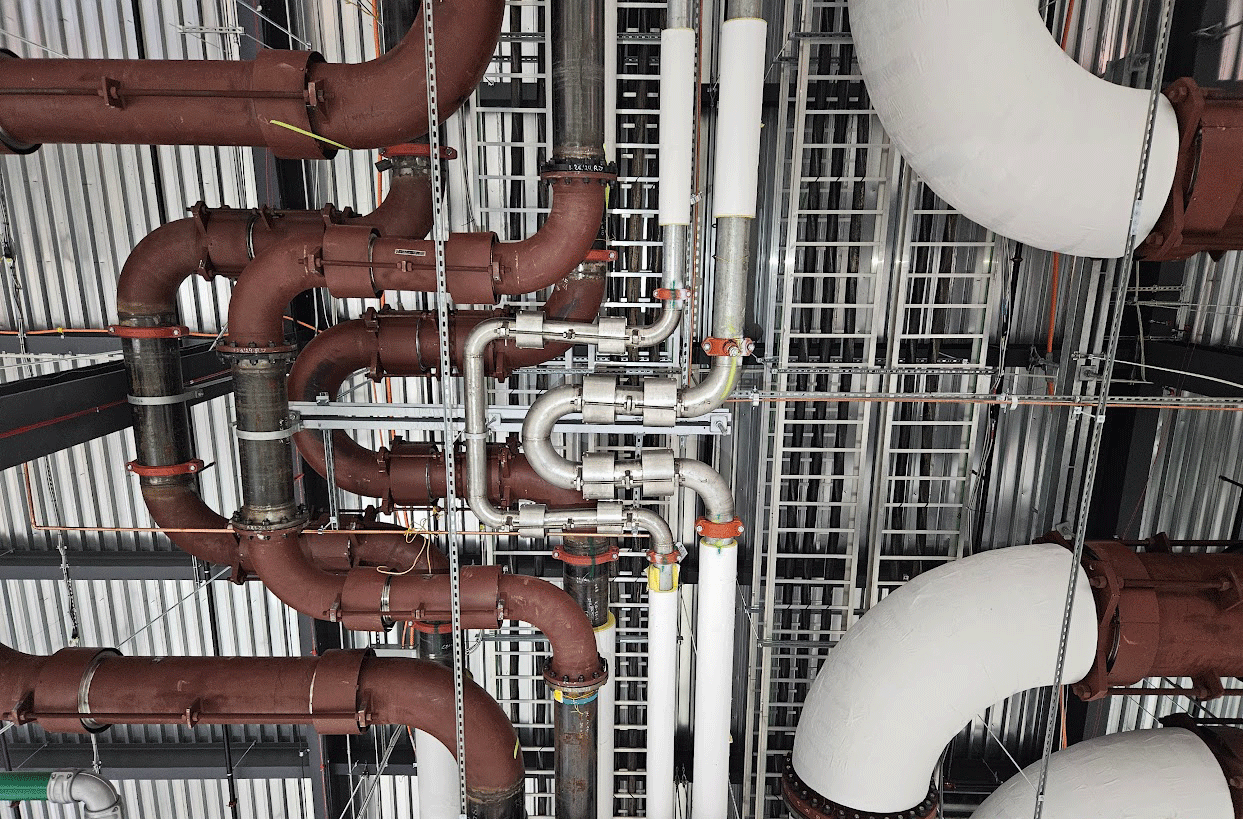

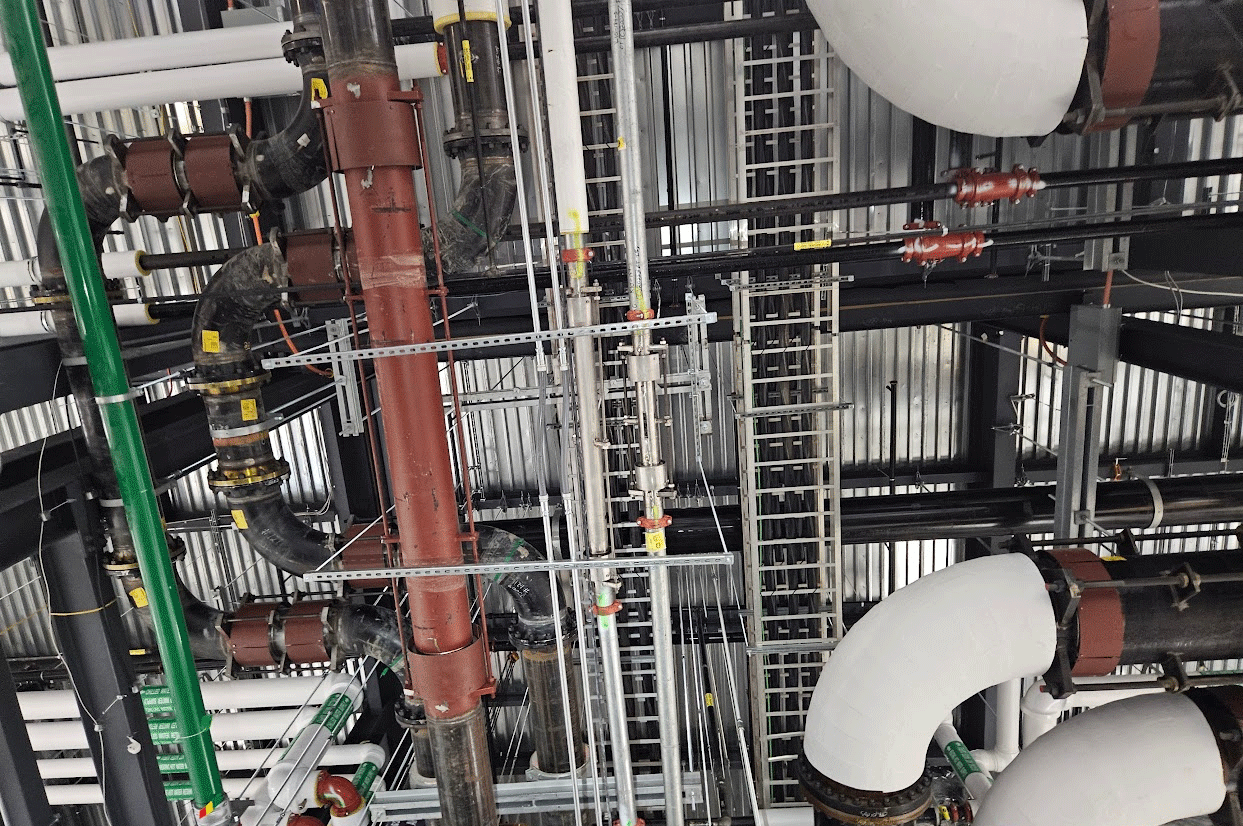

- Space-Saving “Nested” Configuration: Our innovative nested design creates a compact footprint, preventing expansion joints from becoming “clunky” or colliding with one another during seismic activity.

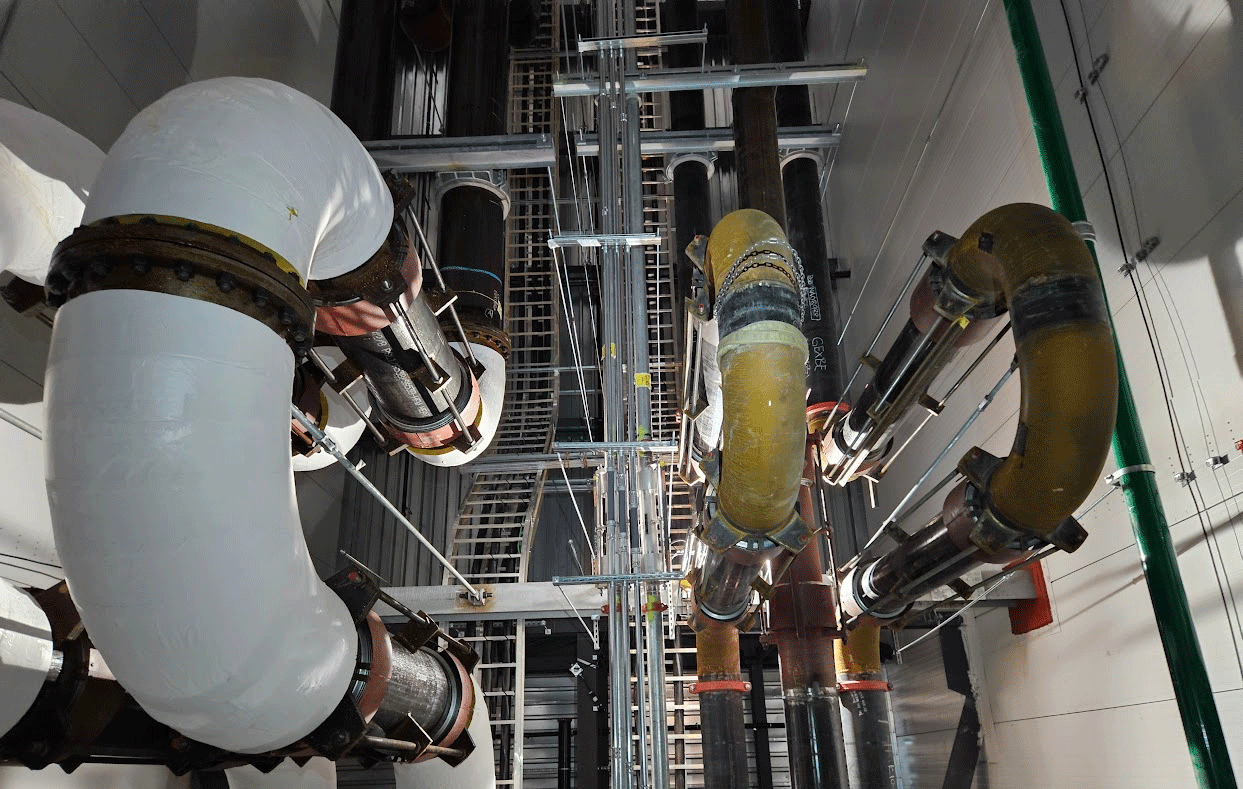

- Integrated Protection and Stability: Units come equipped with covers to protect components during installation and maintenance. Internal liners protect the bellows from the flow media and upset conditions. Additionally, tie rods are utilized to absorb pressure forces, significantly reducing the requirement for numerous anchors.

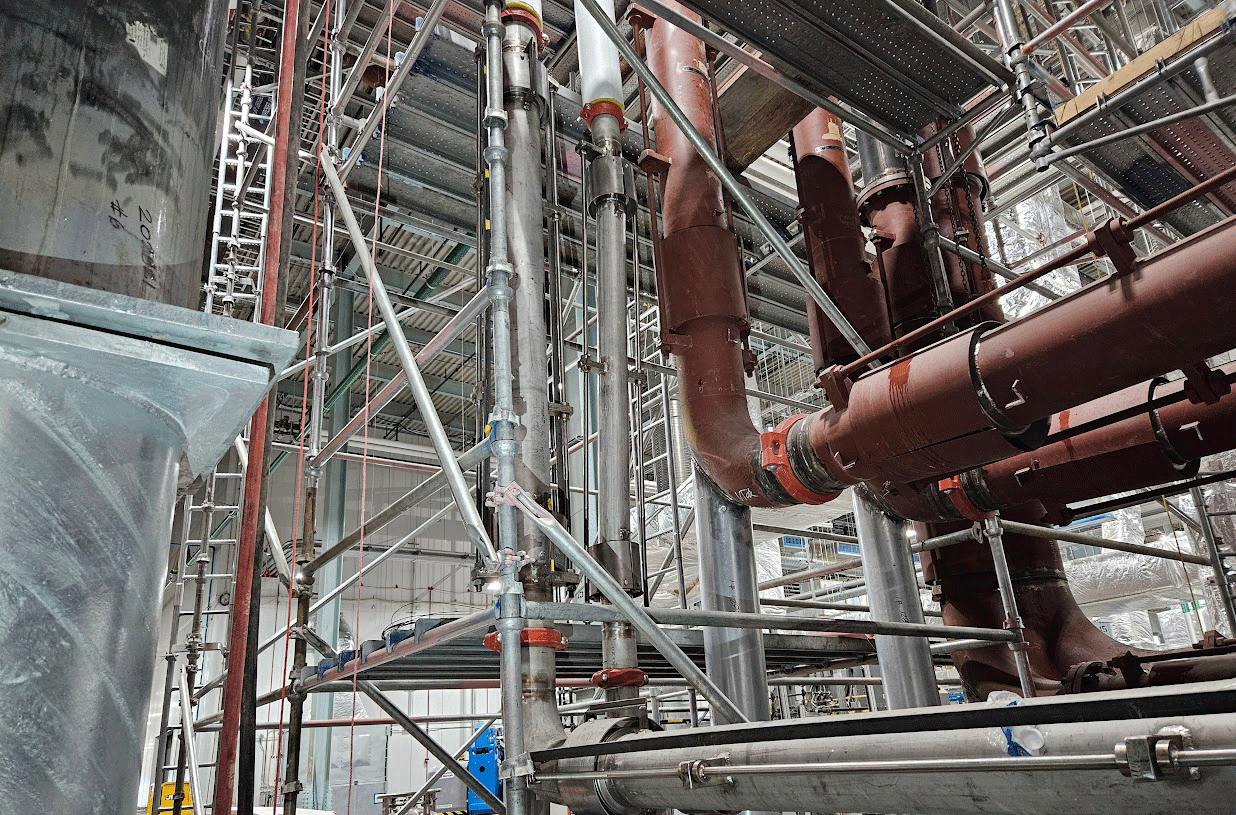

- Seismic Resilience: Specifically engineered to absorb ground movement and accommodate differential settling rates between buildings, ensuring pipeline integrity during seismic events.

- Comprehensive Engineering Support: Our solutions include design engineering, pipe stress analysis for the entire pipeline, and PE stamping to ensure safety and compliance

FAQ

Q: What is the primary advantage of adding bellows to a standard U-Loop?

A: Incorporating bellows into the U-Loop design provides extra flexibility. This allows the system to handle both thermal and seismic movement simultaneously without compromising the pipe’s pressure rating.

Q: What makes the hybrid design of these U-Loops unique?

A: These units represent an industry-first design where bellows are incorporated directly into the U-Loop structure. This hybrid approach provides extra flexibility to handle both thermal and seismic movement without compromising the overall design or the pressure rating of the pipes.

Q: Why is the “nested” design important for large-scale projects, like data centers?

A: Nesting is a key innovation that saves space on crowded jobsites. By nesting larger-diameter loops within smaller-diameter loops it ensures that expansion joints remain compact and do not make contact with one another during seismic shaking, which is critical to maintaining system integrity. This is also a cost-effective approach to minimize supports on the lines by consolidating all the U-loops into a single nested location.

Q: How do these joints protect against ground and building movement?

A: Beyond standard thermal expansion, these U-Loops are engineered to manage differential settlement, where one building sinks or settles at a different rate than surrounding ones. They can also accommodate extreme displacement requirements.

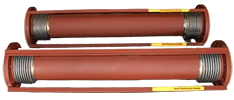

Q: How adaptable is the U-Loop design if project specifications change?

A: The design is highly adaptable. For example, we can engineer U-Loops for extreme seismic requirements (such as 20 inches of movement). However, if site conditions change, we can modify designs mid-project and convert complex U-Loops to single expansion joints where appropriate to save time and costs.