Single Expansion Joints – 12 Inch Nominal Diameter

12 Inch Nominal Diameter

Effective (Thrust) Area: 156.06 in2 (1006.59 cm2)

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section

- To increase cycle life or movements, please refer to the graph on cycle life

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: For appropriate flange temperature/pressure ratings, see catalog flange data

- Torsional spring rate data provided only for modeling expansion joints on computer stress programs. Please consult factory for allowable torsional loadings.

- Overall lengths and weights for unrestrained expansion joints only. Consult factory for information regarding tied, hinged, or gimbal expansion joints.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

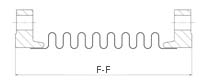

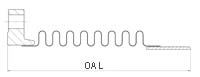

| Diameter | Pressure | Overall Length and Weight | Non-concurrant movements | Spring rates | ||||||||||

| Flanged Ends | Weld Ends | Combination Ends | Axial | Axial | Lateral | Angular | Torsional | |||||||

| Overall Length | Weight | Overall Length | Weight | Overall Length | Weight | Compression | ||||||||

| PSIG | in. | lb. | in. | lb. | in. | lb. | in. | in. | deg. | lb./in. | lb./in. | n./lb./deg. | in./lb./deg. x 106 |

|

| kg/cm2 | mm | kg | mm | kg | mm | kg | mm | mm | Grad | kg/mm | kg/mm | N-M/Grad | N-M/Grad x 105 |

|

| 12 | 80 | 12 | 137 | 16 | 45 | 14 | 91 | 2.94 | 0.53 | 10 | 416 | 2113 | 179 | 0.3358 |

| 5.6 | 305 | 62.3 | 406 | 20.5 | 356 | 41.4 | 74.7 | 13.5 | 11 | 7 | 38 | 18.2 | 0.3415 | |

| 60 | 18 | 144 | 22 | 52 | 20 | 98 | 5.41 | 1.75 | 10 | 238 | 378 | 102 | 0.191 | |

| 4.2 | 457 | 65.5 | 559 | 23.6 | 508 | 44.5 | 137 | 44.5 | 11 | 4 | 7 | 10.4 | 0.1943 | |

| 25 | 24 | 151 | 28 | 58 | 26 | 104 | 8.57 | 4 | 10 | 166 | 128 | 7.1 | 0.1335 | |

| 1.8 | 610 | 68.6 | 711 | 26.4 | 660 | 47.3 | 218 | 102 | 11 | 3 | 2 | 7.2 | 0.1357 | |

| 12 | 210 | 12 | 243 | 16 | 49 | 14 | 146 | 1.41 | 0.21 | 10 | 1952 | 14794 | 840 | 0.6363 |

| 14.8 | 305 | 110 | 406 | 22.3 | 356 | 66.4 | 35.8 | 5.33 | 11 | 35 | 265 | 85.4 | 0.6471 | |

| 210 | 18 | 253 | 22 | 59 | 20 | 156 | 2.68 | 0.78 | 10 | 1051 | 2074 | 453 | 0.3387 | |

| 14.8 | 457 | 115 | 559 | 26.8 | 508 | 70.9 | 68.1 | 19.8 | 11 | 19 | 37 | 46.1 | 0.3445 | |

| 300 | 24 | 296 | 28 | 101 | 26 | 198 | 3.97 | 1.71 | 10 | 1447 | 1295 | 627 | 0.2447 | |

| 21.1 | 610 | 135 | 711 | 45.9 | 660 | 90 | 101 | 43.3 | 11 | 26 | 23 | 63.8 | 0.2488 | |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section

Flanges: ASTM A105.

25-80 PSIG Series: 150 lb. ANSI B16.5 RFSO.

210-300 PSIG Series: 300 lb. ANSI B16.5 RFSO

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A53/A106.

25-80 PSIG Series: Std. Wt. Pipe.

210-300 PSIG Series: Std. Wt. Pipe.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel