Overview and Background

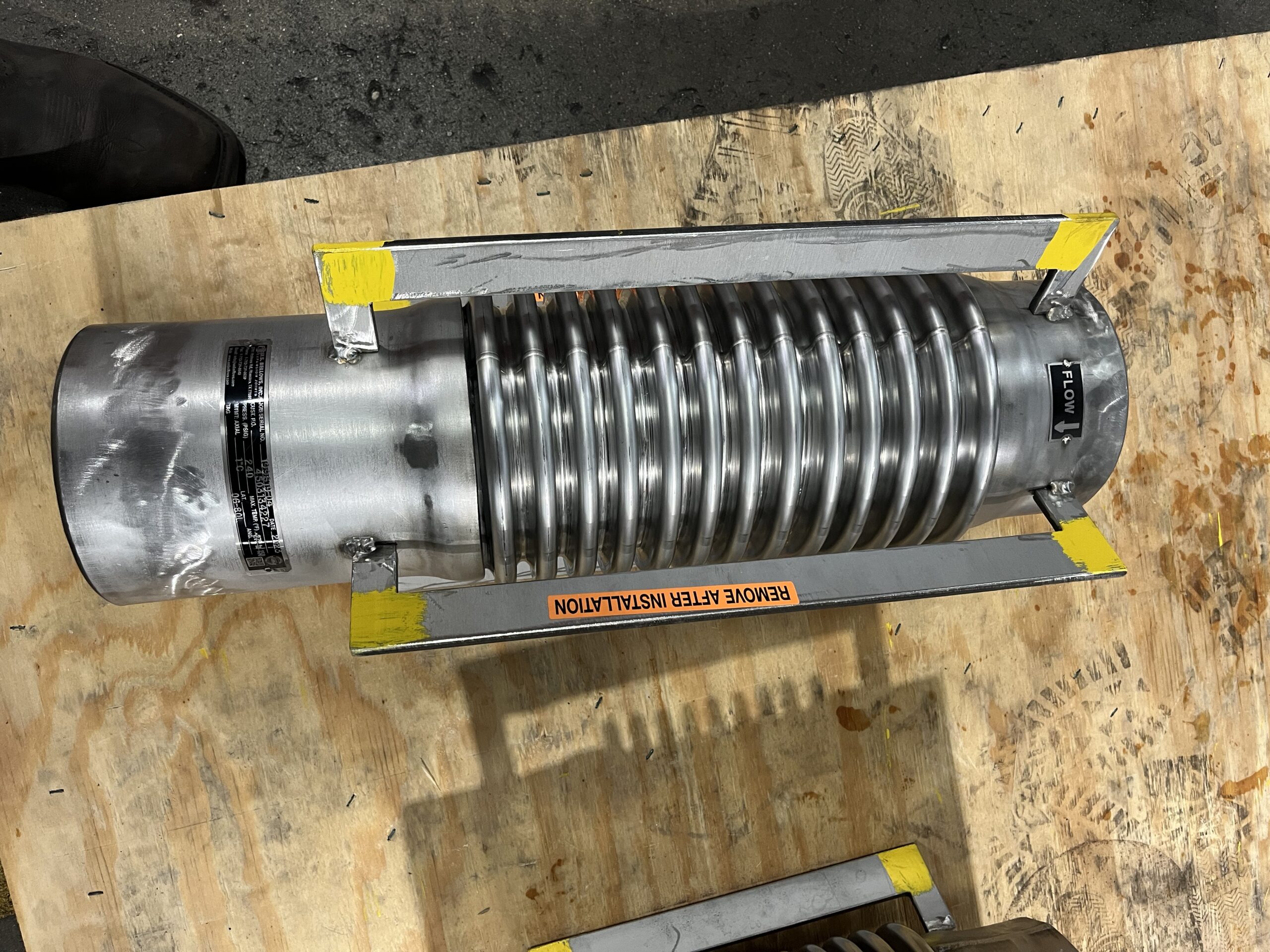

Expansion joints are crucial piping components designed to accommodate the flexibility requirements imposed by thermal expansion, vibration, and mechanical movement. In systems with high flow velocities, expansion joints often incorporate internal sleeves (flow liners) to protect the bellows convolutions by separating them from direct fluid flow and reducing the risk of flow-induced vibration (FIV).

The design of bellows expansion joints is generally governed by the guidelines set by the Expansion Joint Manufacturers Association (EJMA). However, current EJMA standards do not provide detailed guidance or design requirements for internal sleeves operating under reverse flow conditions.

Longitudinal slots in the sleeve are sometimes incorporated to equalize pressure between the inner and outer surfaces of the liner. However, care must be taken when designing these liners for reverse-flow conditions, as the slots act as a weak point in the design.

US Bellows was engaged by the end-user and conducted this case study after being asked to investigate several failures seen in the plant where the expansion joints were subjected to bidirectional flow conditions. Although an overseas company supplied the expansion joints, US Bellows agreed to conduct the analysis.

Problem Description and Field Observations

The failure incident occurred at a Liquefied Natural Gas (LNG) facility with vacuum-jacketed lines. During transient operations, such as process upsets or startup/shutdown, the piping systems experience bidirectional.

- Extent of Failure: Over 80 internal sleeves in the expansion joints showed some sort of deformation or buckling, and 10 liners had collapsed entirely.

The challenge that USB Faced was that the end-user did not want to change the design or replace all 80 expansion joints, as that would require extraordinary effort due to the expansion joints being installed in a double-walled system (vacuum jacket). The customer wanted to replace only the units that had collapsed entirely, and for us to determine a ‘safe-operating’ reverse-flow velocity to prevent further failures.

- Failure Condition: Reverse flow speeds reached up to 40 ft/s when the field failures occurred.

- Mechanism Suspected: The core issue stemmed from the longitudinal pressure equalization slots. Under reverse flow, these slots can deform or close, preventing effective pressure equalization and, in turn, generating damaging forces that can accelerate liner deformation or collapse.

The liner design studied had an outer diameter of 8-¼”, a length of 25”, and 22 individual slots with an opening of 1/32.”

Methodology: Fluid Structure Interaction (FSI) Analysis

To determine the root cause and a safe operating limit, the investigation employed a combination of Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) using a one-way coupled Fluid Structure Interaction (FSI) methodology.

CFD forces (fluid pressures) were generated and then mapped onto the FEA mesh to calculate resulting deformations. The analysis considered the non-linear relationship between large deformations, applied fluid pressures, and the subsequent closure of the pressure equalization slots.

The study analyzed three primary geometries reflecting different operational states and tolerances:

- “Gaps Open”: The as-manufactured, undeformed geometry.

- “Gaps Closed”: A deformed geometry reflecting the start of closure of the original slot open area.

- “Angled Liner”: A geometry simulating installation offset with a 1° angulation forced on the expansion joint.

- Acceptance Criteria: Results were evaluated against ASME Section VIII Division 2 criteria for plastic collapse and local failure.

Key Findings and Root Cause Determination

The FSI analysis confirmed the failure mechanism and established a safe operating limit:

A. Pressure Differential and Plastic Collapse

The study found that the limiting criterion was plastic collapse.

- The pressure differential between the inner and outer sleeve surfaces significantly increased with flow speed, which was because this accelerated the closure of the slots in the liner. Pressure will not equalize effectively as the slots close. This pressure imbalance produced inward radial deformation.

- Crucially, the “gaps closed” model generated a significantly larger pressure differential compared to the “gaps open” model at the same speeds. This result demonstrates that slot closure directly causes increased stress and deformation. In fact, it was found that an already deformed liner increases the pressure differential by a factor of 2.

- The root cause of failure was pressure-differential-induced plastic collapse triggered by the closure of the equalization slots during reverse flow. The deformation increases the differential pressure as the slots close, which in turn increases the force, which further increases deformation, potentially leading to an unstable cycle.

B. Determining the Failure Speed

- The initial (“gaps open”) geometry passed the plastic collapse criterion until approximately 65 ft/s.

- However, when iterating on the deformation (i.e., using the “gaps closed” model), the plastic collapse failure speed dropped sharply to approximately 38 ft/s.

- This calculated failure speed of 38 ft/s aligned closely with the field observations, where complete collapse occurred near 40 ft/s.

C. Influence of Geometry and Turbulence

- Asymmetry/Angulation: Geometric imperfections and installation tolerances were highly influential. The angled liner (1° angulation) case showed drastically higher resulting pressure differentials, suggesting that even small amounts of bellow angulation significantly increase generated forces.

- Transient Effects: Simulations involving turbulent flow conditions (deadleg and mixing flow cases) showed that while forces varied over time, the variations were not at a resonant frequency or high enough magnitude to cause significant deflections. The study concluded that transient effects and turbulence were insignificant as the primary failure mechanism; the collapse was static in nature.

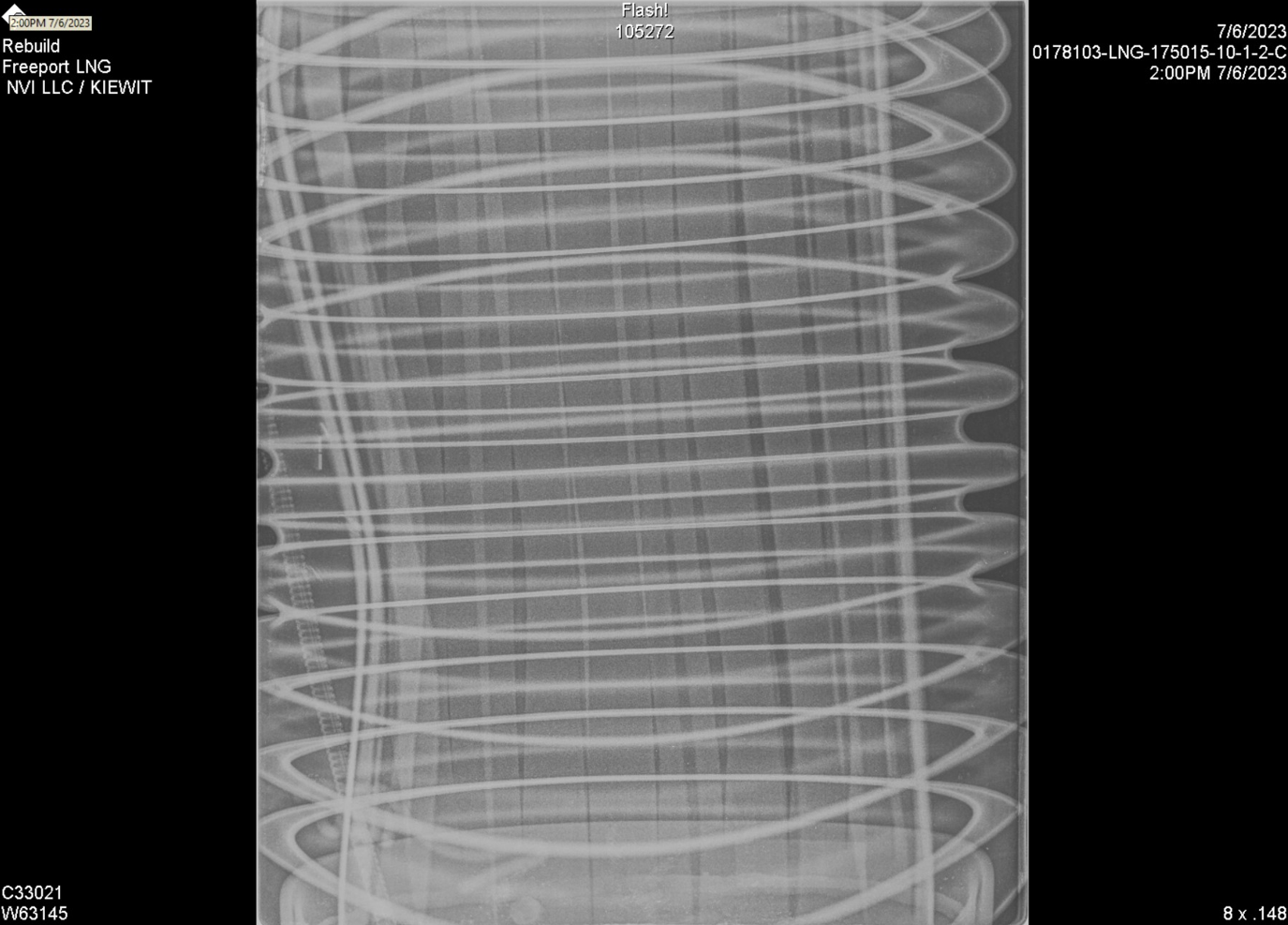

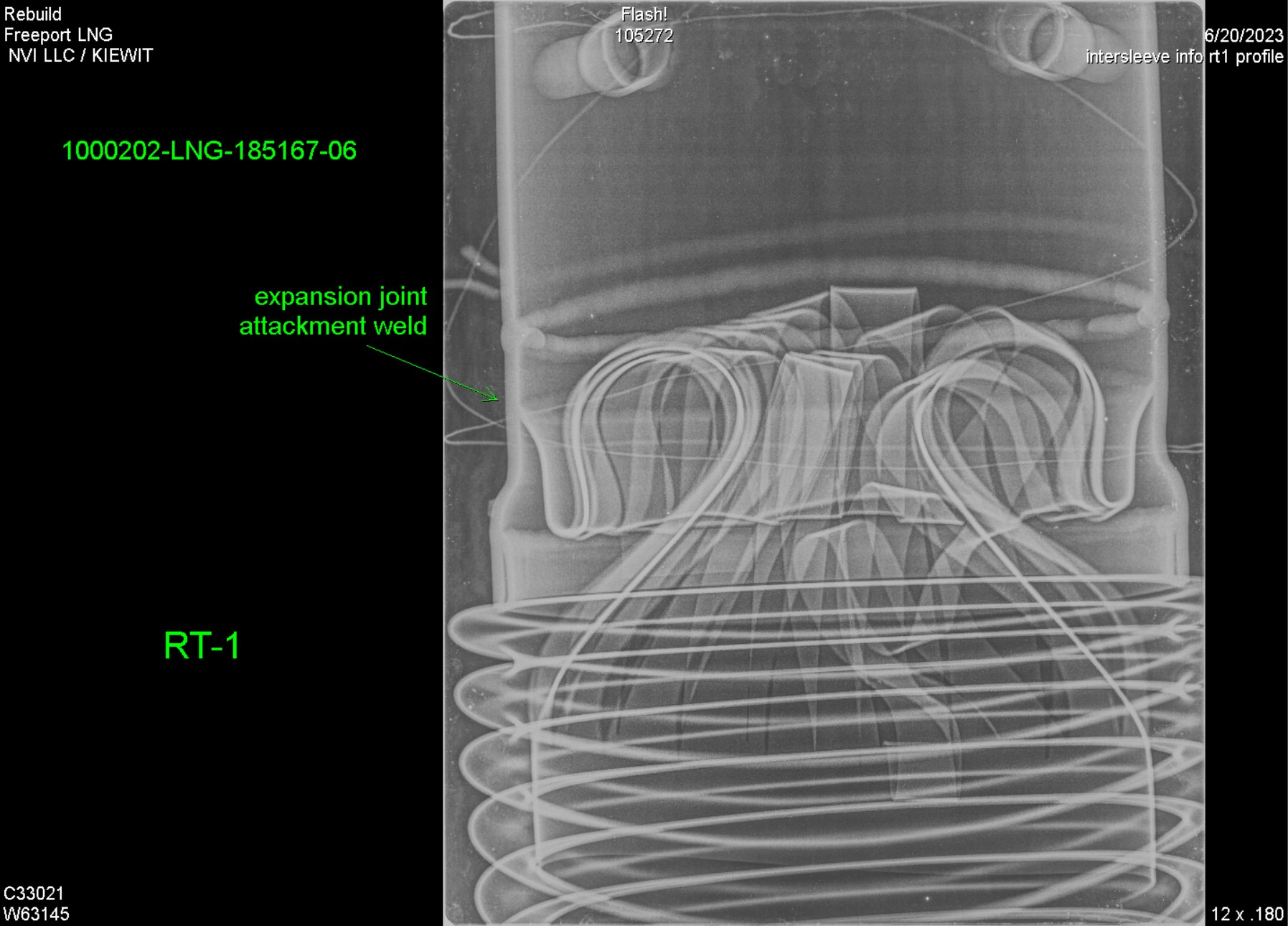

- Field Validation: X-ray inspections of damaged liners in the facility confirmed deformation patterns and extreme plastic deformation consistent with the shapes and locations predicted by the simulation model.

Resolution and Recommendations

The study demonstrated a reliable methodology for qualifying expansion joint liners against reverse flow instability, providing guidance where EJMA standards currently lack detail. A one-way CFD–FEA coupling can effectively predict instability in expansion joint liners under reverse flow, especially when large deflections are involved, provided stability is proven through iterative deformation analysis. The design is considered acceptable if the radially inward deformation does not increase with subsequent iterations, indicating that stability is achieved at that flow speed.

Conclusion: The expansion joint liners failed due to plastic collapse driven by an excessive pressure differential resulting from the closure of pressure equalization slots at high reverse flow speeds (near 40 ft/s).

Our final report established a safe reverse-flow limit for the existing expansion joint design, allowing our client to operate safely as long as the flow velocity is not exceeded.

Finally, this study, its methodology, and its results were submitted and published for the ASME Pressure Vessels and Piping Conference.

——————————————————————————–

An expansion joint internal sleeve is like a dam with controlled overflow gates. If the water flow suddenly reverses (reverse flow), the equalization gates (slots) might get pushed shut by the new pressure direction. If the gates close, the pressure differential across the dam wall (the sleeve) spikes dramatically, causing the entire structure to collapse or buckle because the pressure is no longer balanced.