Single Expansion Joints – 50 Inch, 52 Inch, 54 Inch Nominal Diameter

50 Inch, 52 Inch, 54 Inch Nominal Diameter

Notes:

- Rated life cycle at 650°F is 3000 cycles for any one tabulated movement.

- To combine axial, lateral and angular movements, please refer to the how to order section

- To increase cycle life or movements, please refer to the graph on cycle life

- Rated bellows extension is equal to rated axial movement. Provided bellows is precompressed the amount of design extension. Installed overall length will decrease by the amount of precompression.

- Maximum test pressure: 1.5 X rated working pressure.

- Bellows rated for 650°F: For appropriate flange temperature/pressure ratings, see catalog flange data

- Torsional spring rate data provided only for modeling expansion joints on computer stress programs. Please consult factory for allowable torsional loadings.

- Overall lengths and weights for unrestrained expansion joints only. Consult factory for information regarding tied, hinged, or gimbal expansion joints.

- Pressure thrust load applied to adjacent pipe anchors/equipment when unrestrained expansion joints are used.

| Dia | Pressure | Overall Length and Weight | Non-concurrant movements | Spring rates | ||||||||||

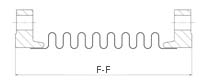

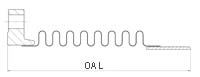

| Flanged Ends | Weld Ends | Combination Ends | Axial | Lateral | Angular | Axial | Lateral | Angular | Torsional | |||||

| Overall Length | Weight | Overall Length | Weight | Overall Length | Weight | Compression | ||||||||

| PSIG | in. | lb. | in. | lb. | in. | lb. | in. | in. | deg. | lb./in. | lb./in. | in./lb./deg. | in./lb./deg. x 106 |

|

| kg/cm 2 | mm | kg | mm | kg | mm | kg | mm | mm | Grad | kg/mm | kg/mm | N-M/Grad | N-M/Grad x 105 |

|

| 50 | 75 | 13 | 953 | 16 | 197 | 15 | 575 | 2.1 | 0.11 | 5 | 2786 | 177720 | 1643 | 35.9278 |

| 5.2 | 330 | 433 | 406 | 89.5 | 381 | 261 | 53.3 | 2.79 | 5 | 50 | 3180 | 1682.4 | 36.5386 | |

| Effective Area | 21 | 1002 | 24 | 246 | 23 | 624 | 5.4 | 0.55 | 10 | 1393 | 22215 | 8271 | 17.9639 | |

| 533 | 455 | 610 | 112 | 584 | 284 | 137 | 14 | 11 | 25 | 398 | 841.2 | 18.2693 | ||

| 2138 in2 | 29 | 1050 | 32 | 294 | 31 | 672 | 8.1 | 1.24 | 10 | 929 | 6582 | 5514 | 11.9759 | |

| 13,792 cm2 | 737 | 477 | 813 | 134 | 787 | 305 | 206 | 31.5 | 11 | 17 | 118 | 560.8 | 12.1795 | |

| 52 | 70 | 13 | 1005 | 16 | 205 | 15 | 605 | 2.72 | 0.13 | 6 | 2899 | 199415 | 18562 | 40.405 |

| 4.9 | 330 | 457 | 406 | 93.2 | 381 | 276 | 69.1 | 3.3 | 6 | 52 | 3569 | 1887.8 | 41.0919 | |

| Effective Area | 21 | 1056 | 24 | 256 | 23 | 656 | 5.44 | 0.54 | 10 | 1450 | 24927 | 9281 | 20.2025 | |

| 533 | 480 | 610 | 116 | 584 | 298 | 138 | 13.7 | 11 | 26 | 446 | 943.9 | 20.5459 | ||

| 2305 in2 | 29 | 1106 | 32 | 306 | 31 | 706 | 8.16 | 1.2 | 10 | 966 | 7386 | 6187 | 13.4683 | |

| 14,870 cm2 | 737 | 503 | 813 | 139 | 787 | 321 | 207 | 30.5 | 11 | 17 | 132 | 629.2 | 13.6973 | |

| 54 | 70 | 13 | 1057 | 16 | 213 | 15 | 635 | 2.72 | 0.13 | 6 | 3013 | 222807 | 20740 | 45.2394 |

| 4.9 | 330 | 480 | 406 | 96.8 | 381 | 289 | 69.1 | 3.3 | 6 | 54 | 3987 | 2109.3 | 46.0085 | |

| Effective Area | 21 | 1110 | 24 | 266 | 23 | 688 | 5.44 | 0.52 | 10 | 1506 | 27851 | 10370 | 22.6197 | |

| 533 | 505 | 610 | 121 | 584 | 313 | 138 | 13.2 | 11 | 27 | 498 | 1054.6 | 23.0043 | ||

| 2478 in2 | 29 | 1162 | 32 | 318 | 31 | 740 | 8.15 | 1.16 | 10 | 1004 | 8252 | 6913 | 15.0798 | |

| 15,989 cm2 | 737 | 528 | 813 | 145 | 787 | 336 | 207 | 29.5 | 11 | 18 | 148 | 703.1 | 15.3362 | |

Materials

Bellows: A240-T304. Alternate materials available upon request. Refer to the materials section

Flanges: ASTM A105.

70-75 PSIG Series: 125 lb. Lt. Wt. FSSO.

Plate flanges and angle flanges available for low pressure systems.

Pipe: ASTM A285-C.

70-75 PSIG Series: 0.375-inch wall.

Liners: A240-T304.

Covers: Carbon steel.

Tie Rods, Hinges, Gimbals: Carbon steel