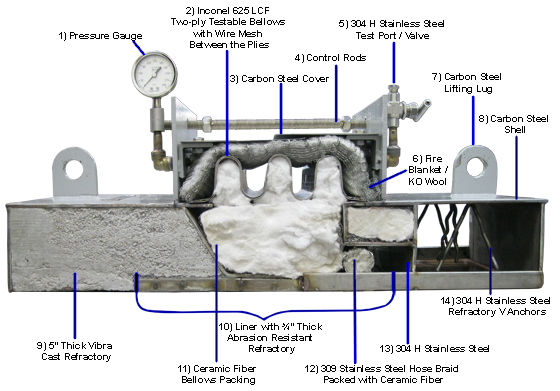

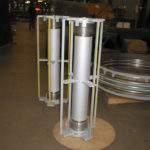

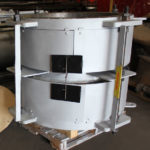

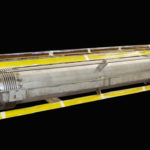

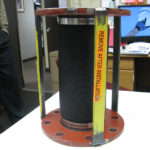

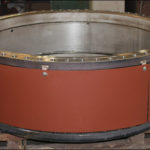

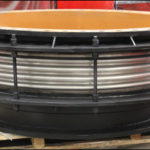

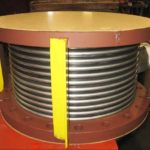

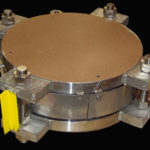

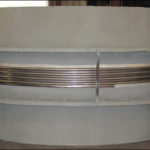

Type: Externally Pressurized Expansion Joints Size: 59 9/16″ Long | 3″ Nominal Pipe Size Material: 304 Stainless Steel | Chrome-Moly Design: 1020°F Operating Temp. @ 140 psig | 11.75″ Axial Testing: 100% Dye-Penetrant | X-Ray | Hydro-tested This externally pressurized expansion joint was designed by U.S. Bellows for a reformer unit at a refinery in Saudi Arabia. It is 59 9/16″ long with a nominal pipe size of 3″. The bellows were fabricated from 304 stainless steel and the pipe, flanges and hardware from chrome-moly. The unit is designed for an operating temperature of 1020°F at 140 psig. 11.75″ of axial compression and 1.25″ of extension. The expansion joint was 100% dye-penetrant tested, x-ray tested the bellows, and hydro-tested prior to shipment