|

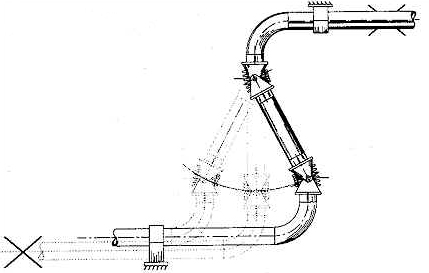

When thermal expansion or other movements want to bend a pipe, in order to lower stresses, a controlled bending point can be added with a hinge or gimbal pipe expansion joint. The hinged unit will limit bending to only one plane, and the gimbal will permit bending in all planes. The piping is always in tension because the pressure thrust is contained within the system, and main pressure thrust anchors are not required. Generally, only guides and intermediate anchors are needed, as shown in the examples. The full weight of the pipe between these pipe expansion joints can be carried by them. With a proper hinge and gimbal structure, the weight of additional pipes can also be supported as well as wind loading. EXAMPLE 17

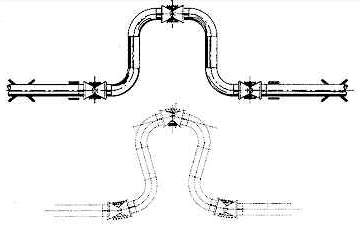

Two hinged expansion joints in a straight pipe run will permit lateral deflection of the pipe, just as a universal expansion joint will. However, the axial thermal growth will not be absorbed within the pipe expansion joints. This example uses a flexible straight pipe section between two elbows to accept the large thermal expansion of long pipe runs on either side. Planar guides, or guides which permit movement in a plane perpendicular to the pipe as well as axially, should be added because some pipe bending may occur. EXAMPLE 18  |

|

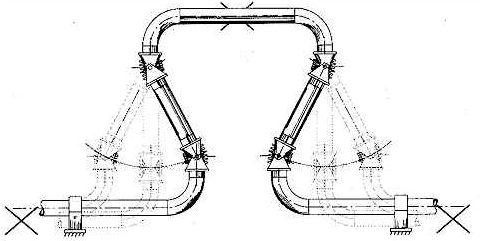

In this example a highly flexible pipe loop is created with a double set of the arrangement shown in Example 17. The top of the loop is anchored with an intermediate anchor, and each side operates independently of the other. EXAMPLE 19 |

|

|

|

|

|

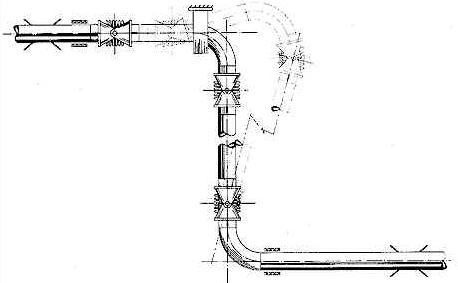

A highly efficient replacement for a rigid pipe loop is depicted here with three hinged expansion joints. Using four 90 degree elbows, this “loop” has only two “legs” with short pipe lengths. These features develop much lower flow losses than a common pipe loop for the same axial travel. Pipe guides should be used near the outer pipe expansion joints. Only intermediate anchors are needed. EXAMPLE 20 |

|

|

|

|

The three pin arch system shown in this example accepts deflections in all directions and operates in the same manner as the loop shown in Example 19. Because the movement of each bellows is highly controlled and limited to bending only, it is one of the most reliable arrangements for large pipe and vessel deflections. When hinged expansion joints are used, the movements are confined to a single plane. When at least two gimbal joints are used, the movements accepted can be in all directions and in any plane. |